The GPPH SMART economical line of welding tables was created with users in mind who need solid and functional solutions but do not require the advanced features offered by professional welding tables. GPPH SMART represents the perfect combination of performance and affordability, tailored to the needs of both hobbyists and smaller workshops.

|

|

This description applies to the product Welding Table GPPH SMART 12 MM 2400×1200 mm grid 100x100mm – this is the most versatile system.

|

|

The milled and chamfered holes in the table top facilitate easy mounting and dismounting of tools during your work, thanks to the precise fitting of the holes to the tools. This also contributes to reduced wear – you don’t need much force for assembly and disassembly. This design is the best available solution on the welding table market! The tolerance of the welding table holes is ±0.05 mm.

The engraved scale on the table top consists of vertical and horizontal lines in a 100x100mm grid. It serves as a reference point when assembling structures and mounting tools. Using measuring tools, you can properly position your construction to achieve the required dimension.

Load capacity of the GPPH SMART 15 table: 1800 kg. (for SMART 12 – 1200 kg)

Differences from traditional GPPH welding tables

Unlike our traditional professional tables, which are designed to meet the requirements of the most advanced applications, GPPH SMART focuses on basic functionality and ease of use. GPPH professional tables offer greater durability and advanced configuration options that are needed in intensive industrial environments. In addition, traditional GPPH professional welding tables have denser table top ribbing and a different leg attachment. They also differ in the profile of the leg design and the holes in the table side plates - traditional tables have 3 rows of holes, while the GPH SMART line has 2 rows.

In addition, the colour scheme of the legs of the GPPH SMART economy welding tables differs from that of the standard GPPH products.

The SMART line is the answer to the needs of a market demanding lower-cost solutions.

Comparison of ribbing

Ribbing for a traditional welding table, 2400x1200mm |

Ribbing for SMART 2400x1200mm welding table |

TECHNICAL PARAMETERS COMPARISON

| Series of traditional welding tables GPPH PLUS | GPPH SMART 12MM series of economic welding tables |

|---|---|

| Flatness tolerance: ±0.3 mm over the entire top* | Flatness tolerance: ±0.5 mm over the entire top* |

| 3 rows of holes on side wall | 2 rows of holes on side wall |

| Hole tolerance: ±0.05 mm | |

| Milled and chamfered holes | |

| Chamfered holes from bottom | |

| Milled table top edges | |

| Leg profile: 80x80x4mm | Leg profile: 60x60x4mm |

| Load capacity: 500kg/leg max. load capacity table with 4 legs: 2000kg |

Maximum load capacity: 1200kg |

| Number of size versions: 10 | Number of size versions: 5 |

| Side wall deflection tolerance: ±0,3° | Side wall deflection tolerance: ±0,35° |

| Available hole grids: 100x100mm, 50x50mm, diagonal | Available hole grids: 100x100mm |

*provided that the table is leveled correctly.

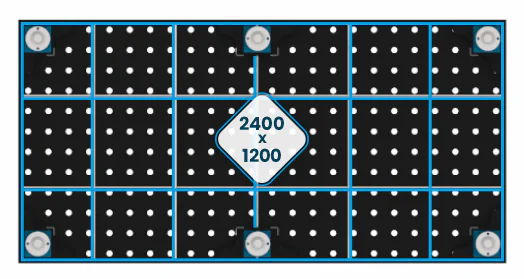

LEG MOUNTING COMPARISON

Leg mounting in the SMART welding table |

Leg mounting in the traditional welding table |

COMPARISON OF HOLES IN THE SIDE WALLS

Table top and side walls in the SMART welding table |

Table top and side walls in the traditional welding table |