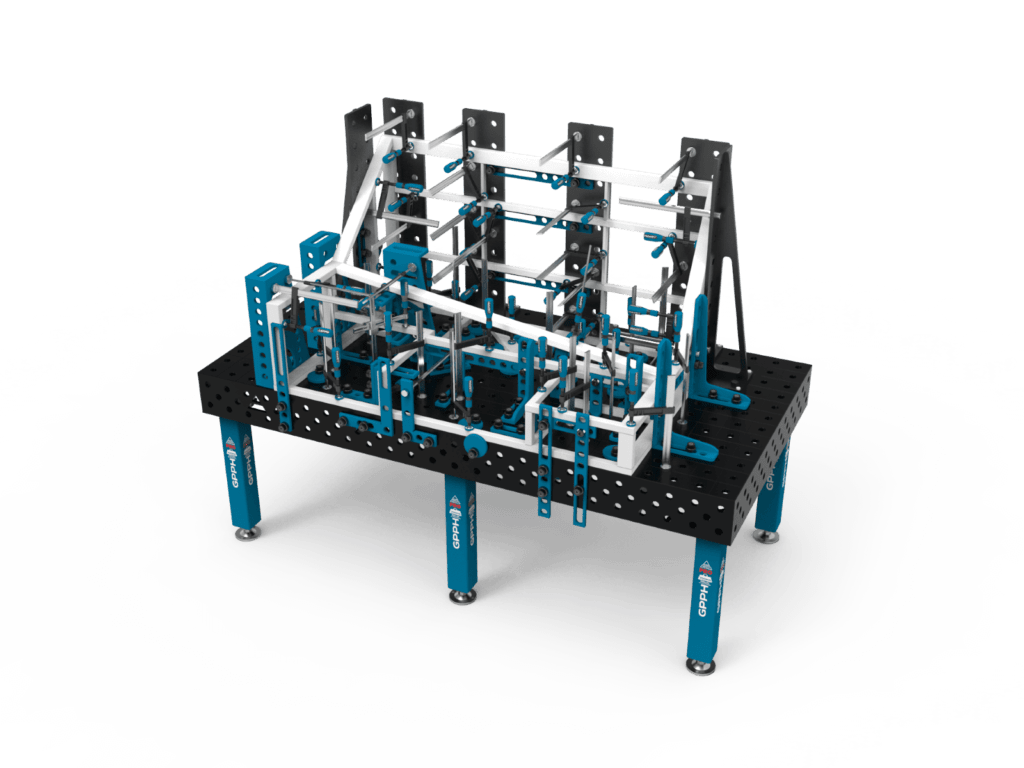

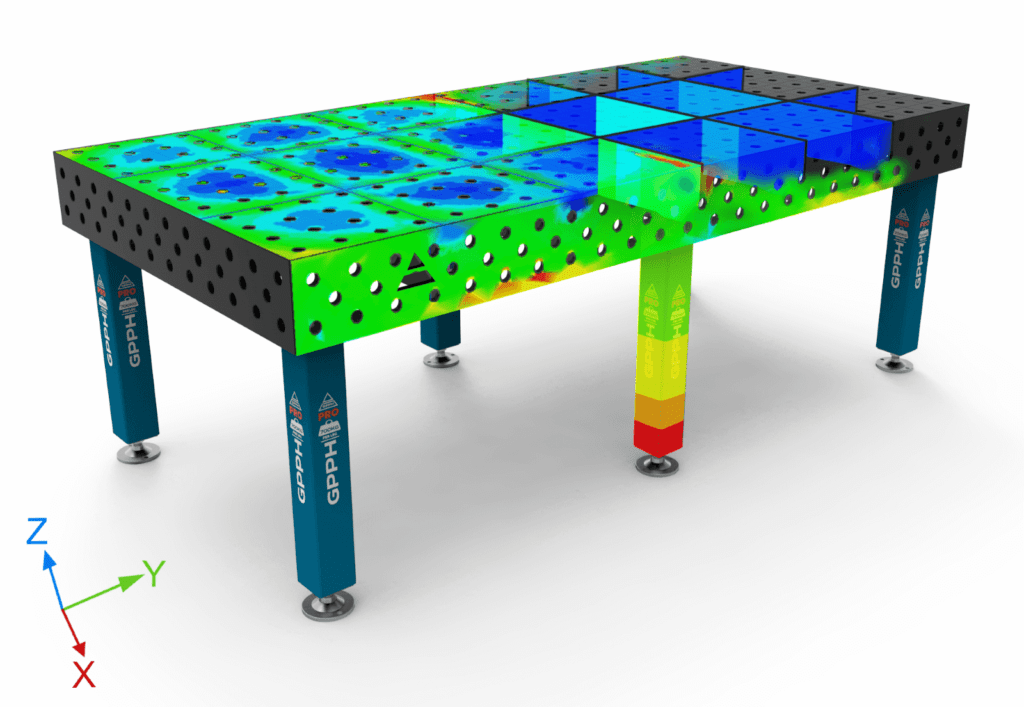

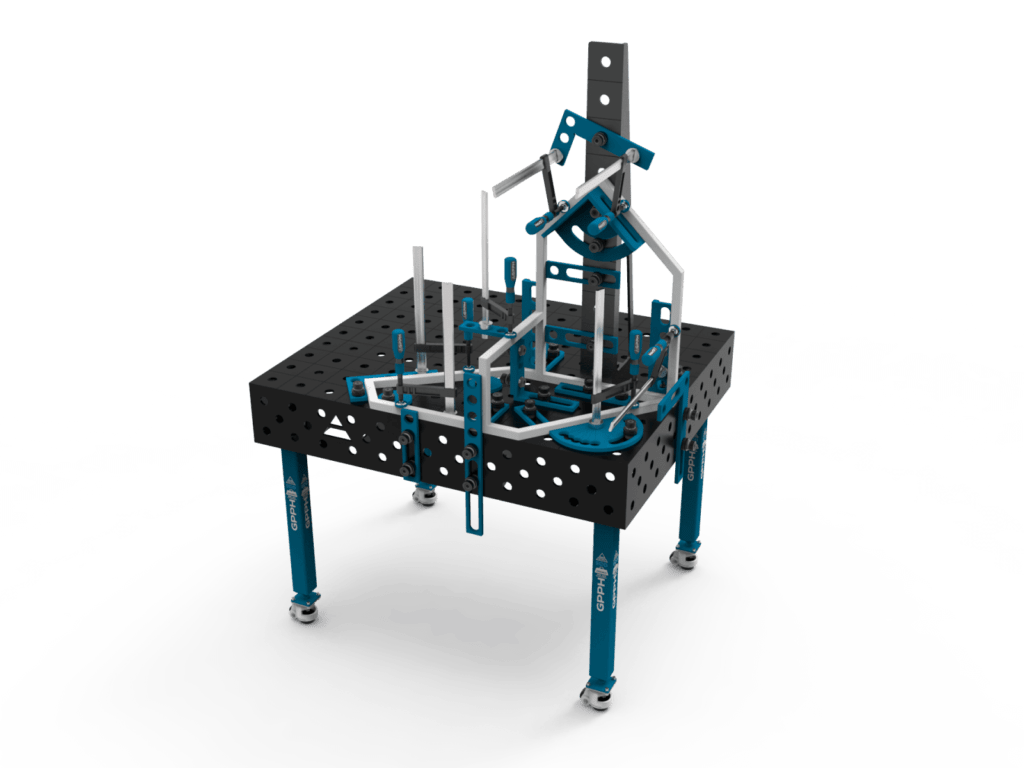

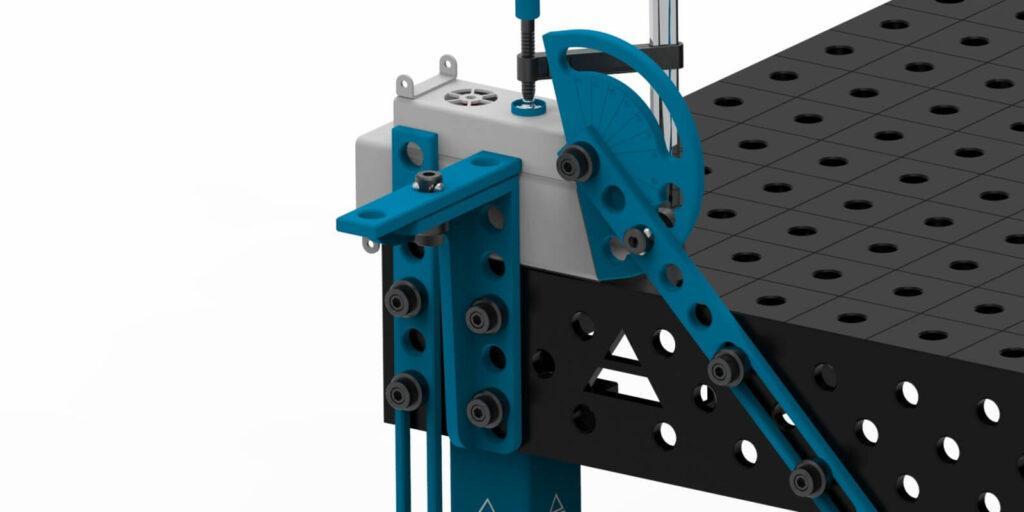

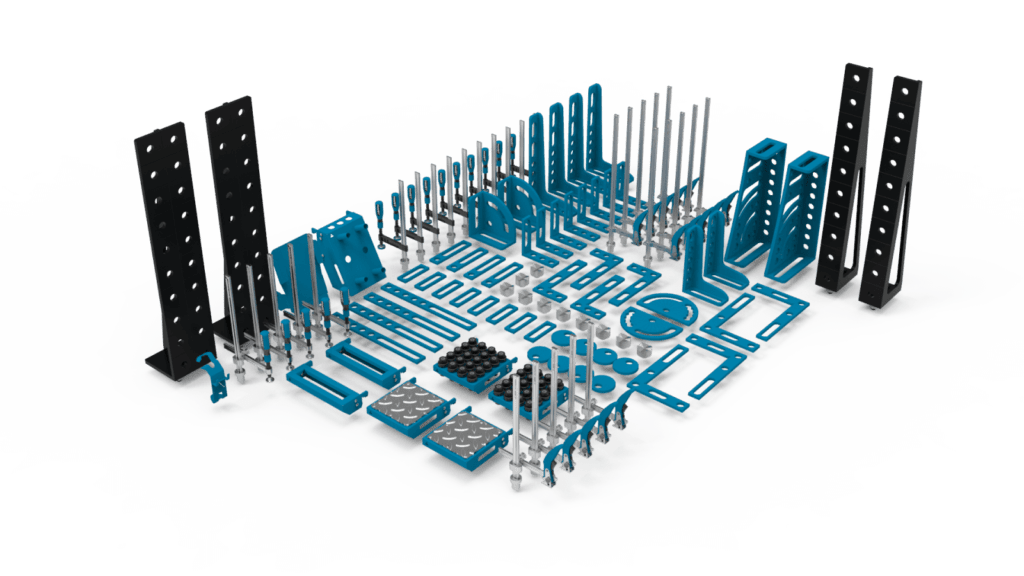

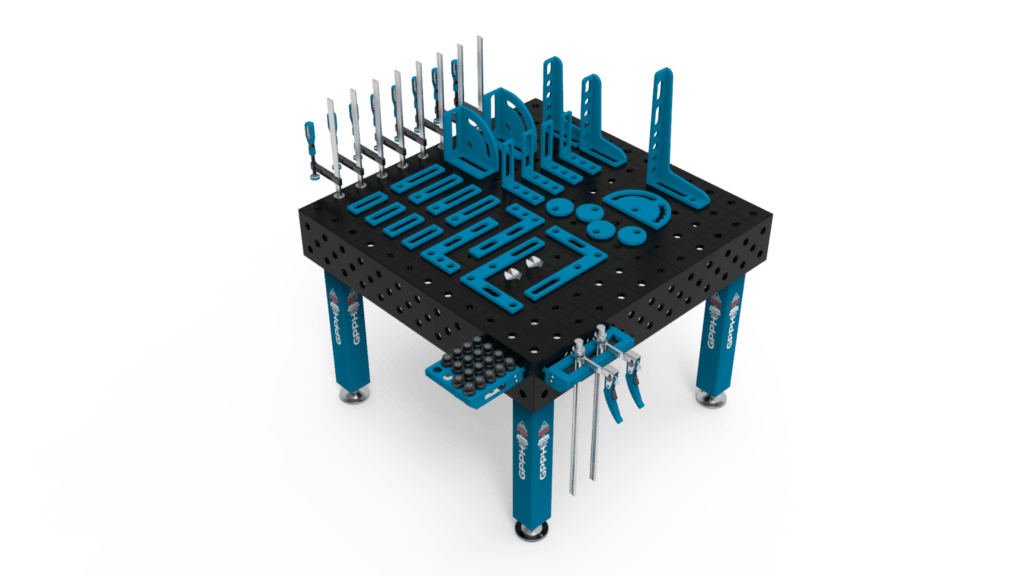

Of heavy-duty structures. It is ideal for advanced welding and metalworking projects where exceptional strength and precision are required.

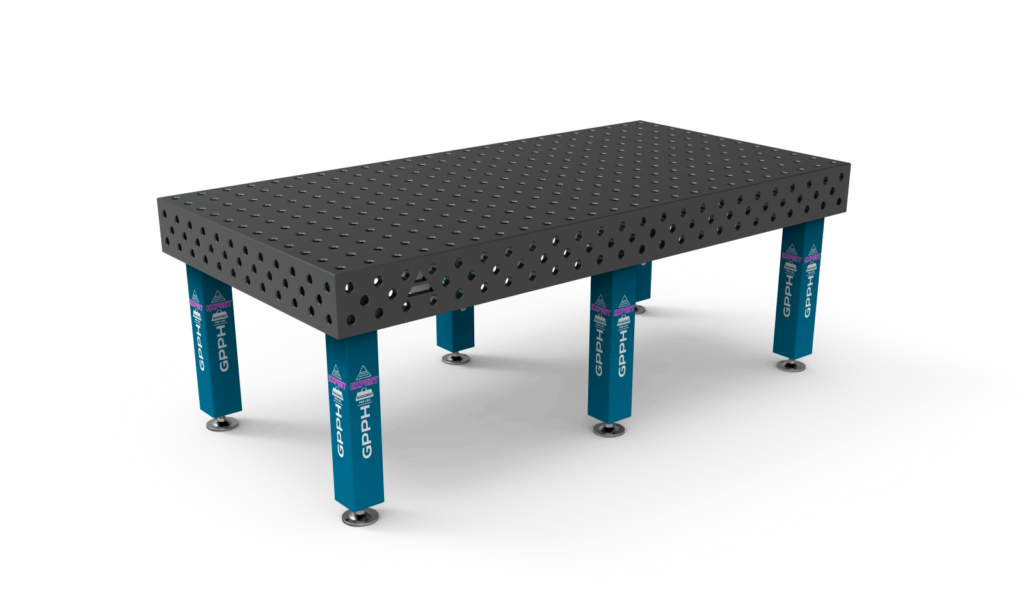

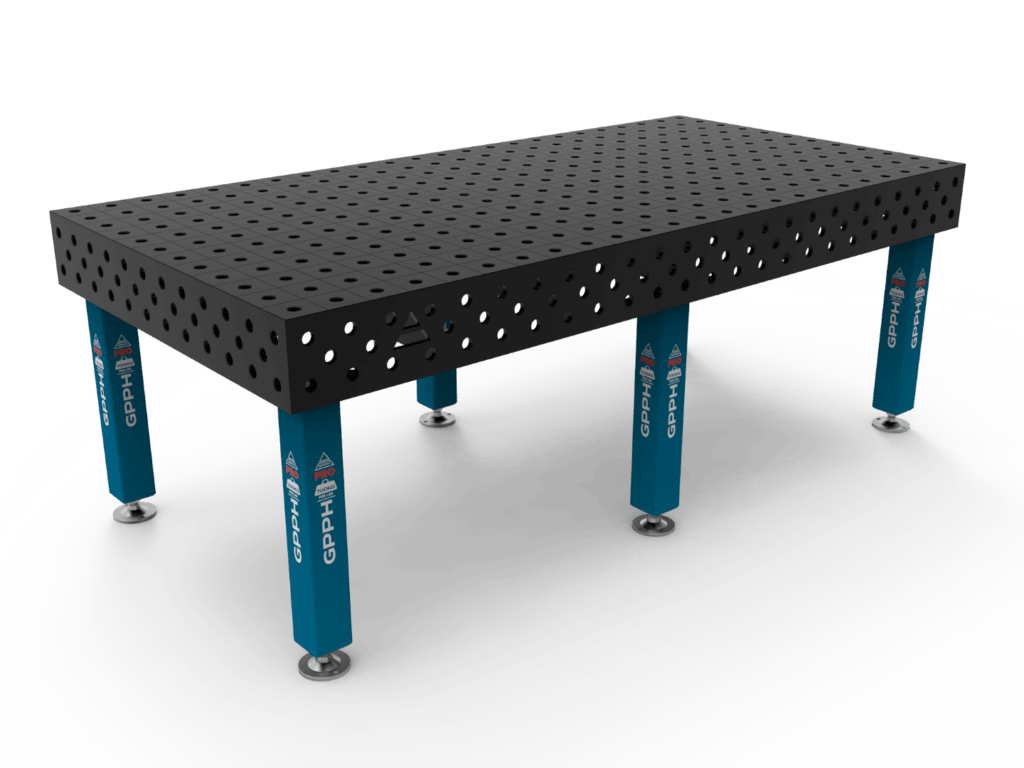

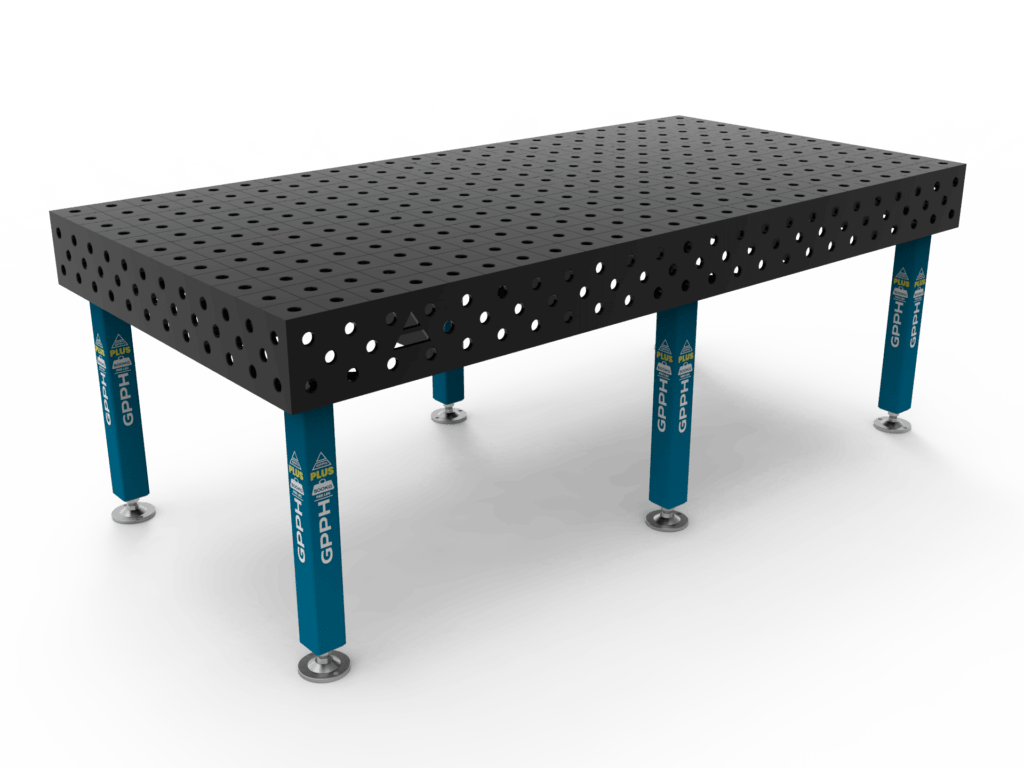

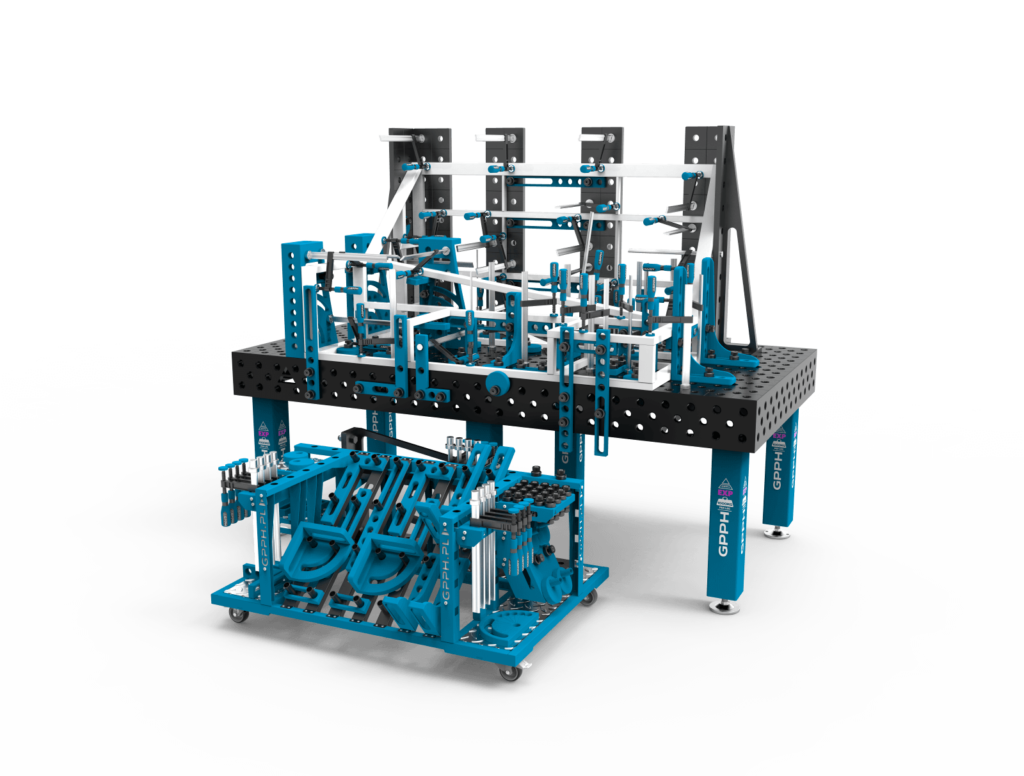

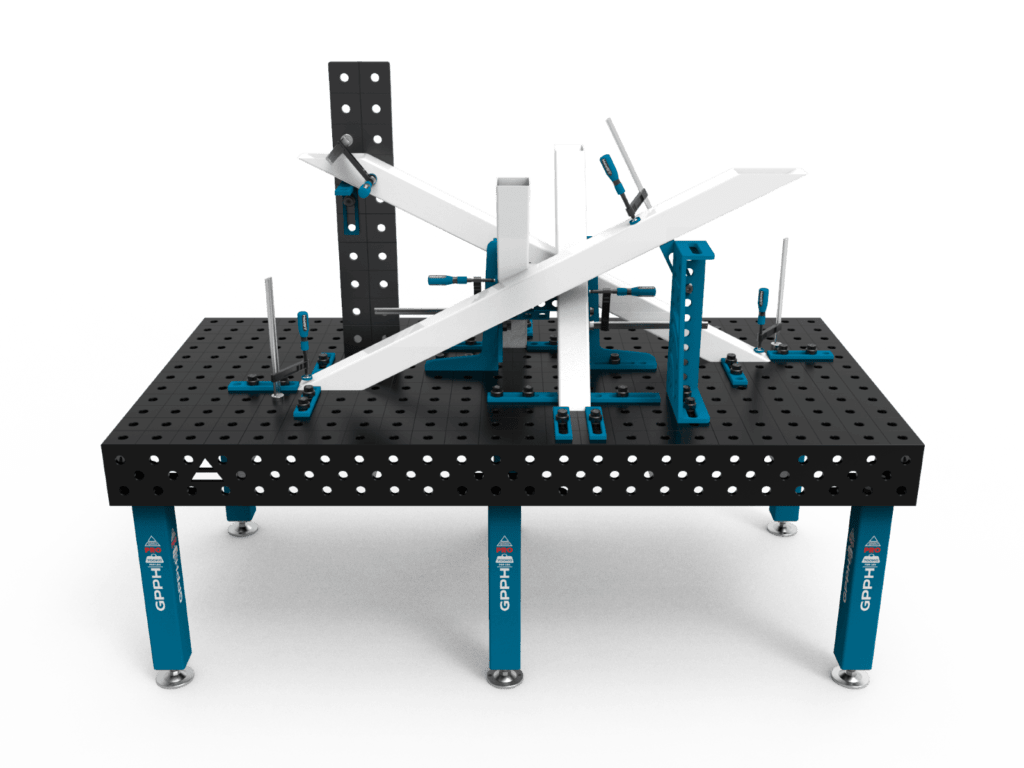

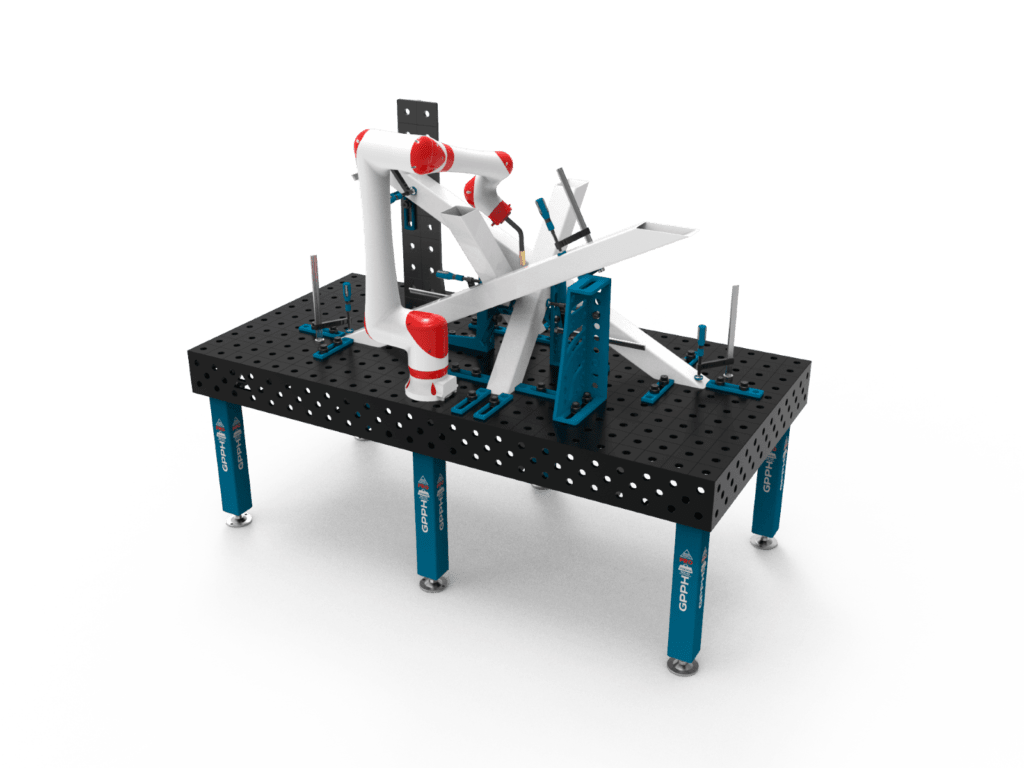

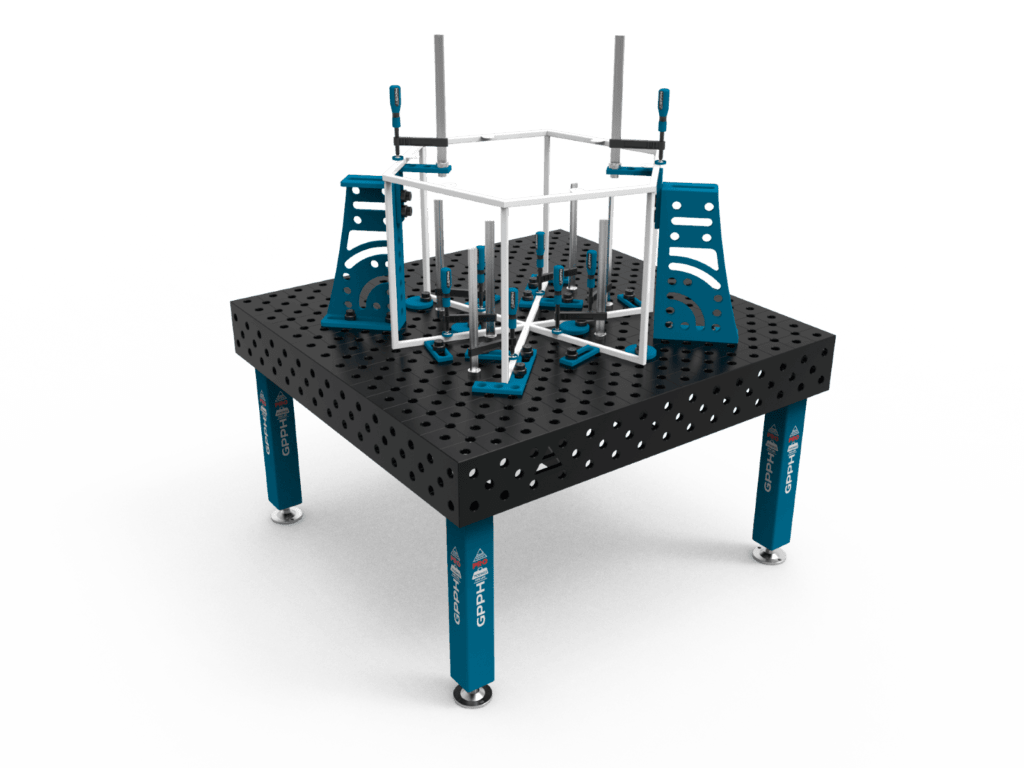

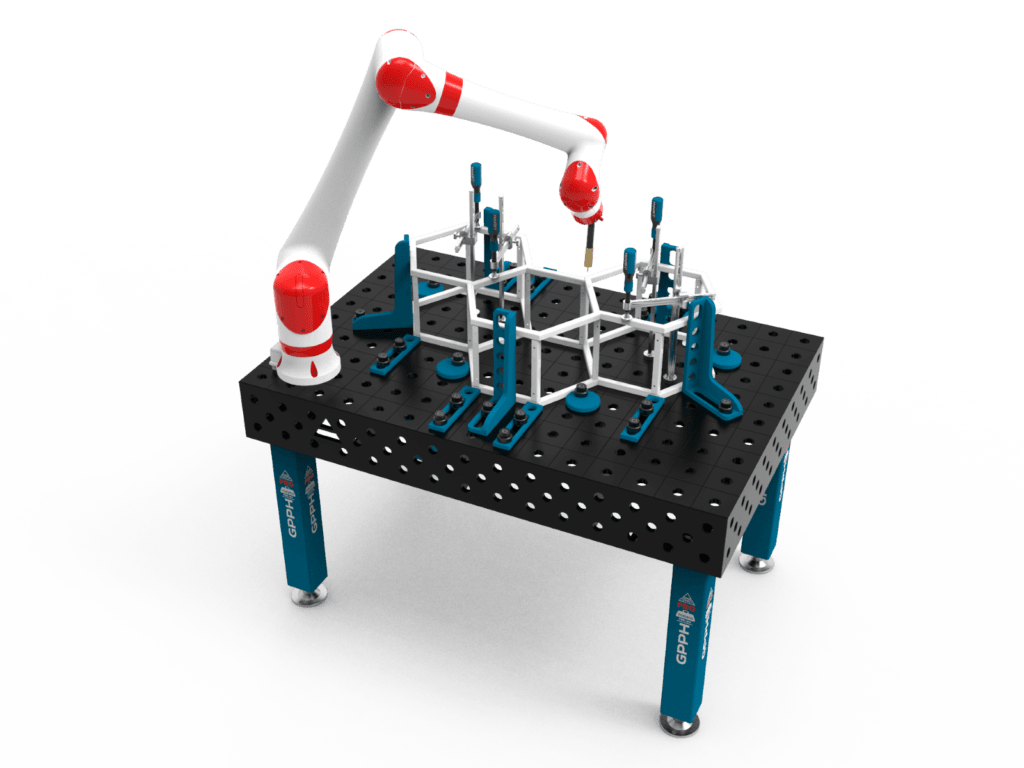

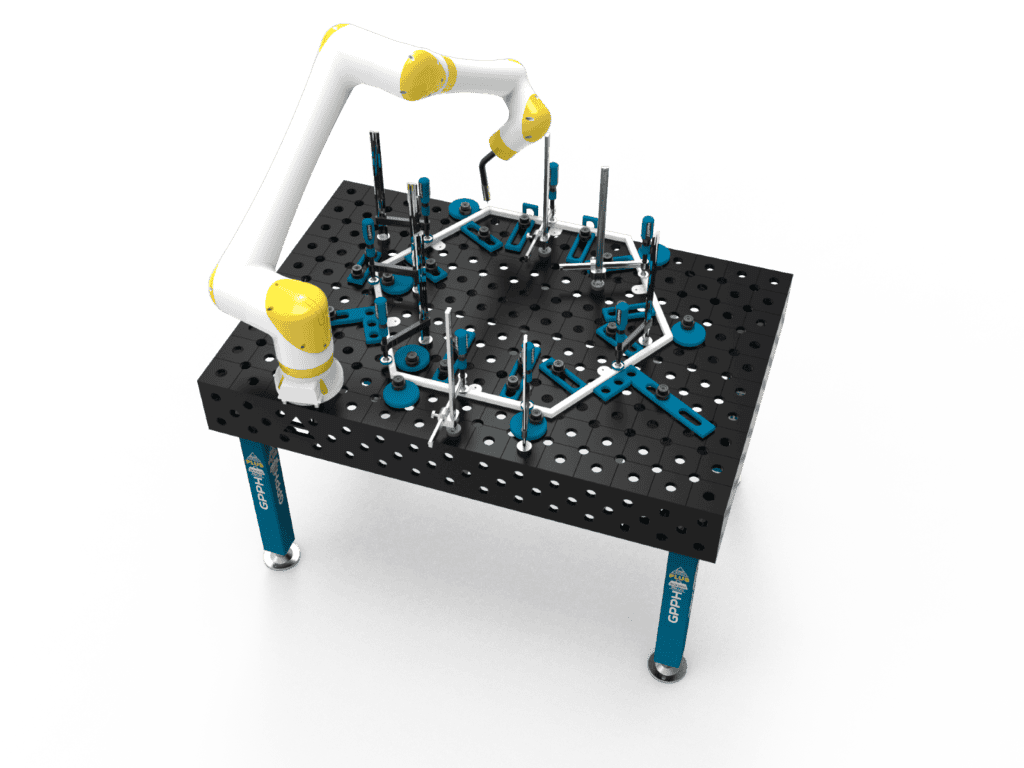

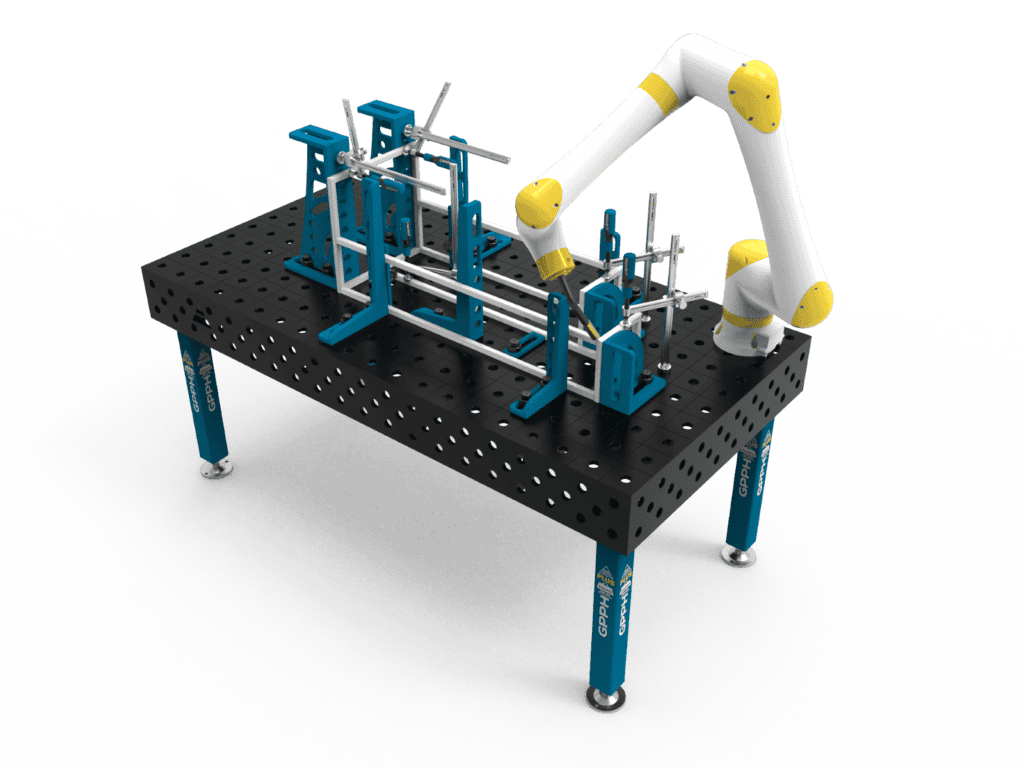

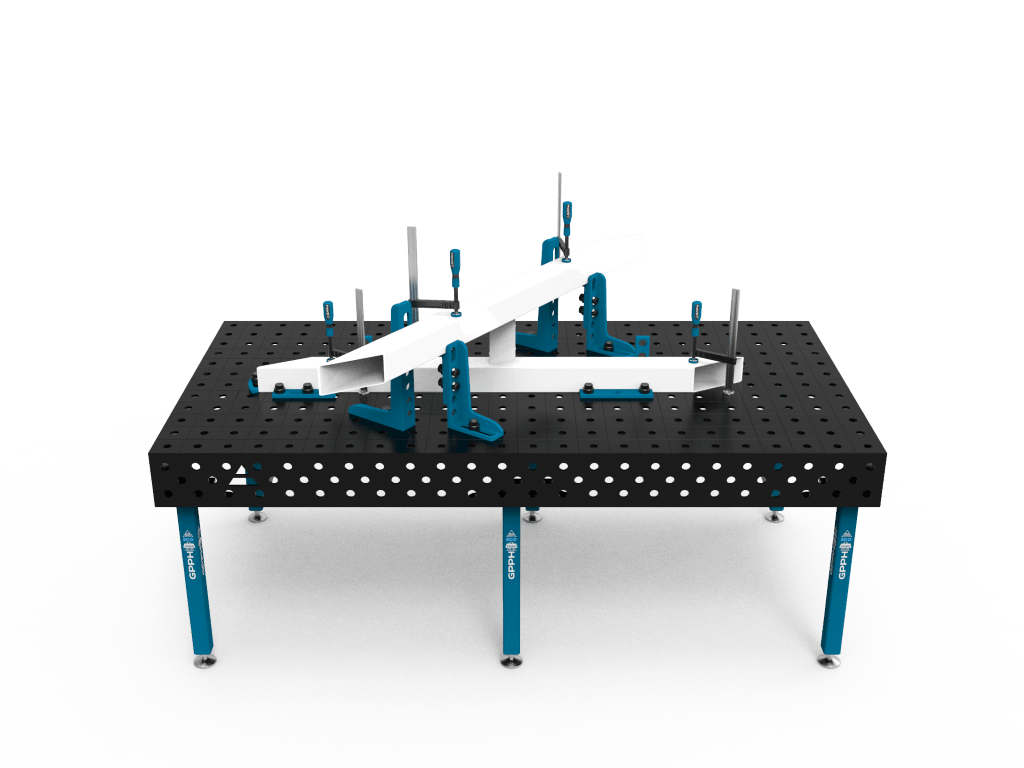

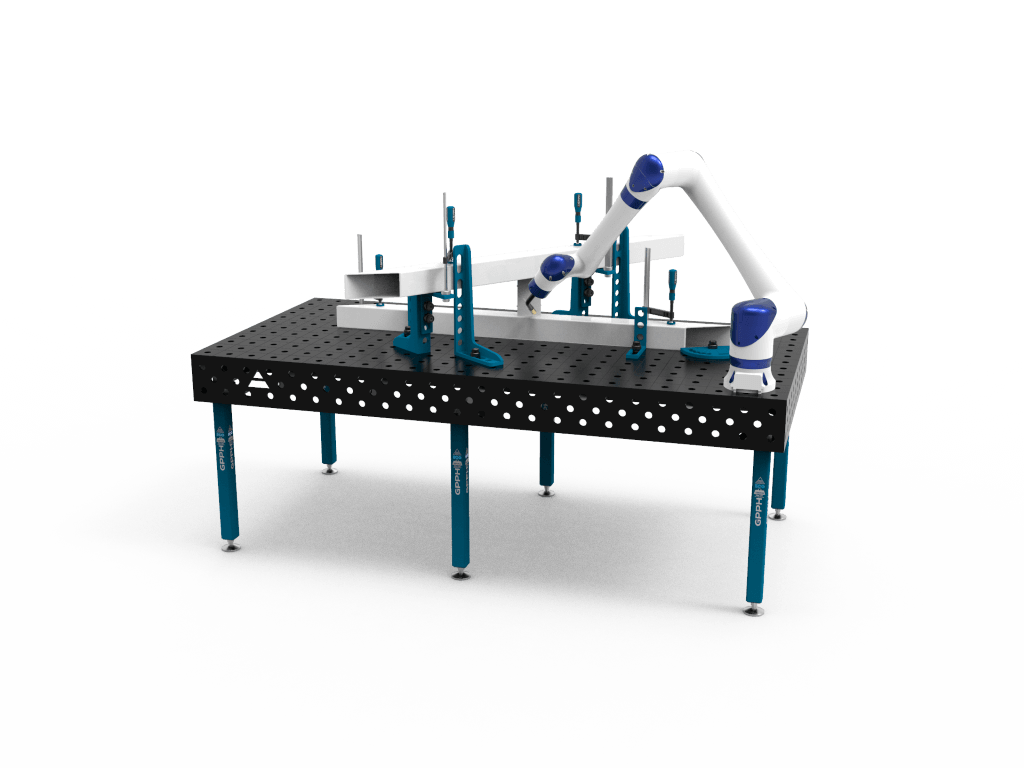

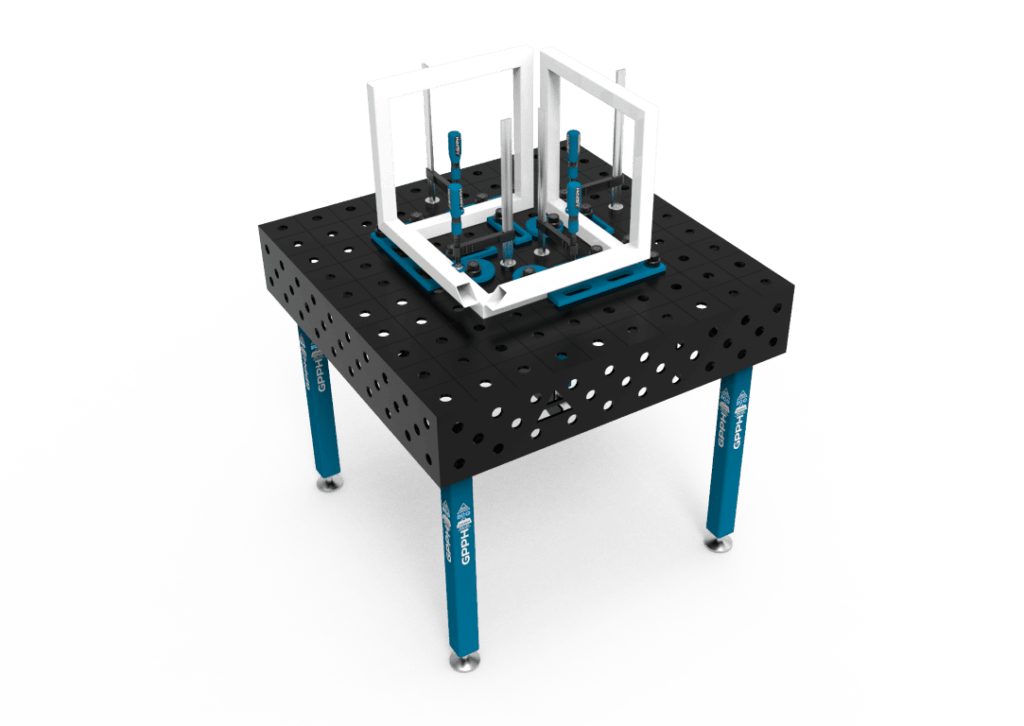

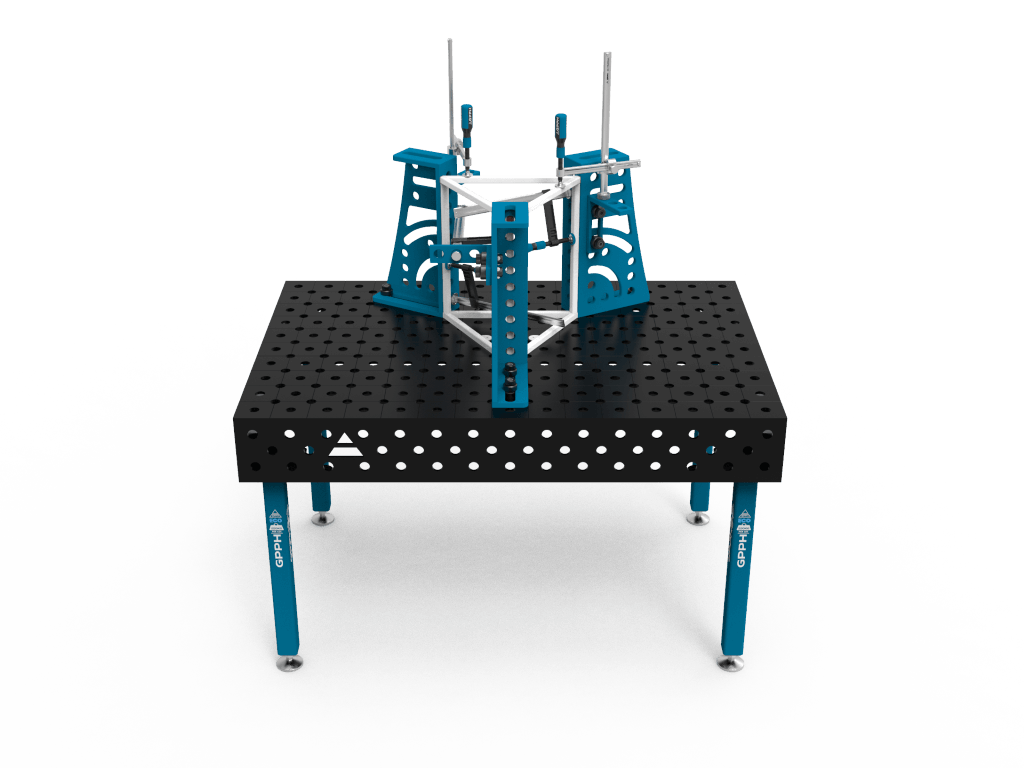

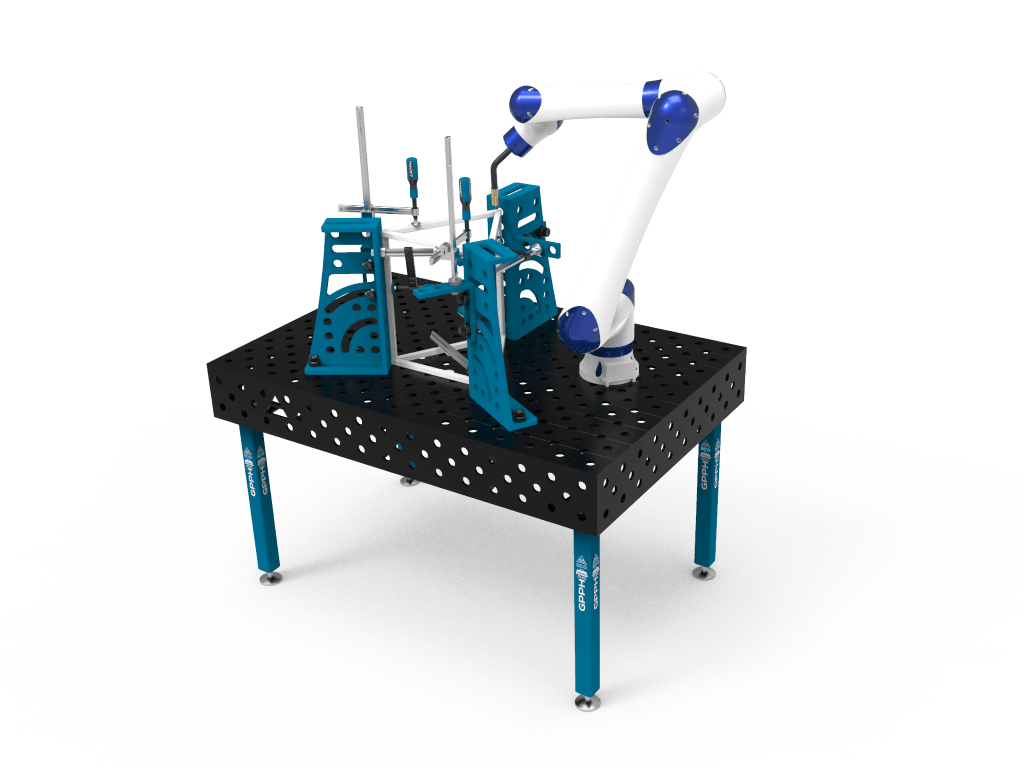

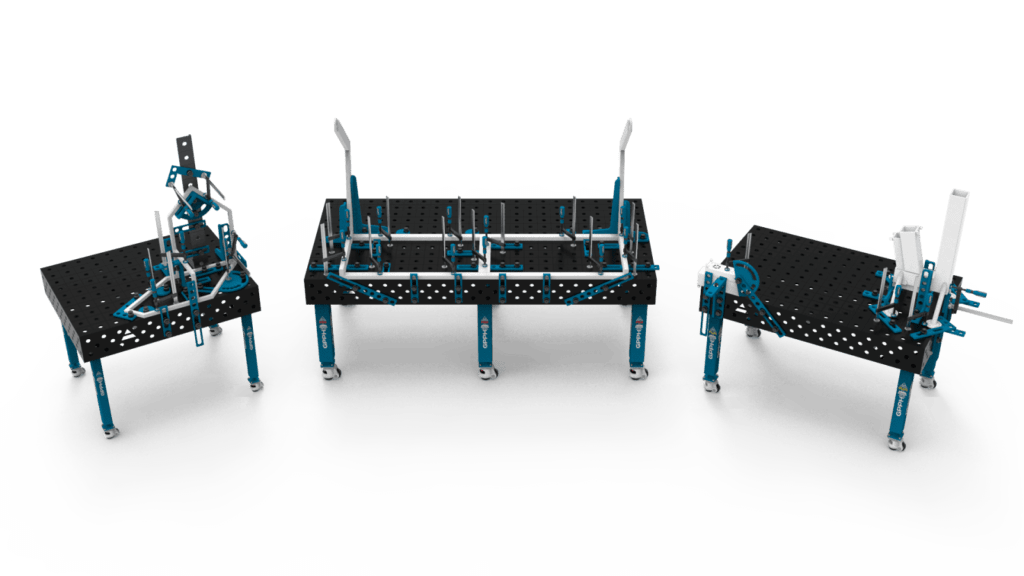

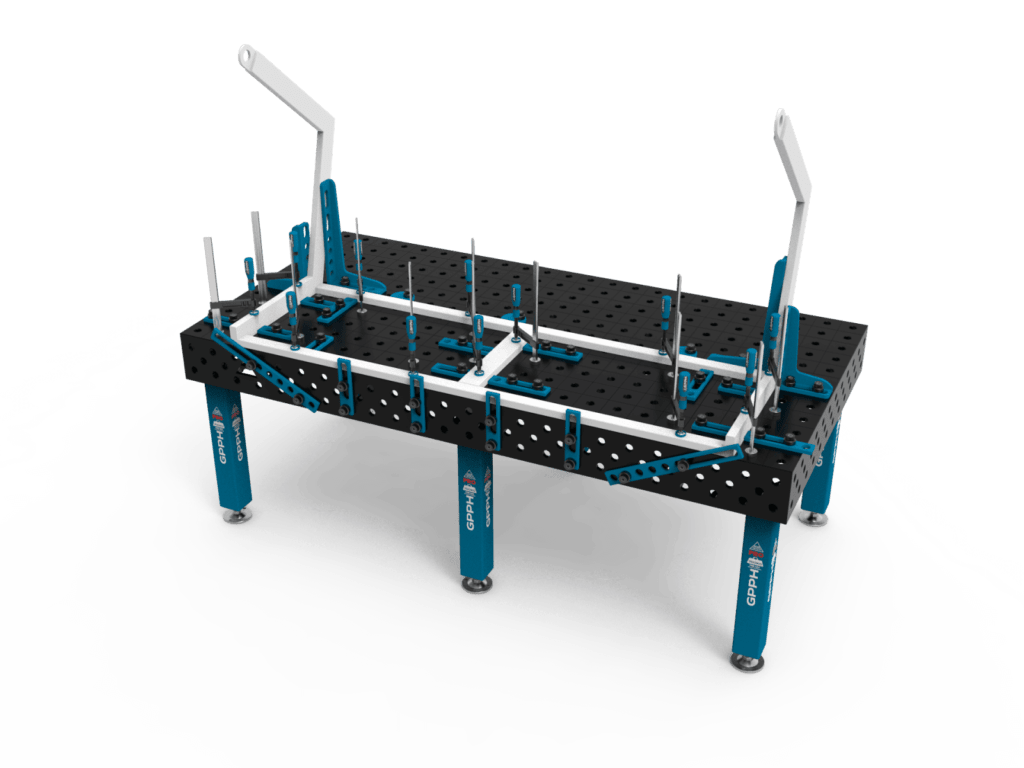

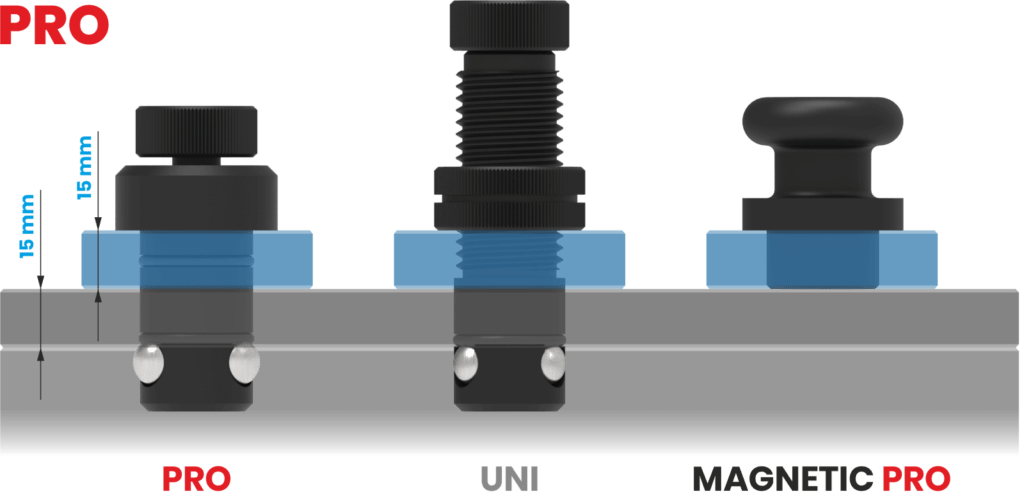

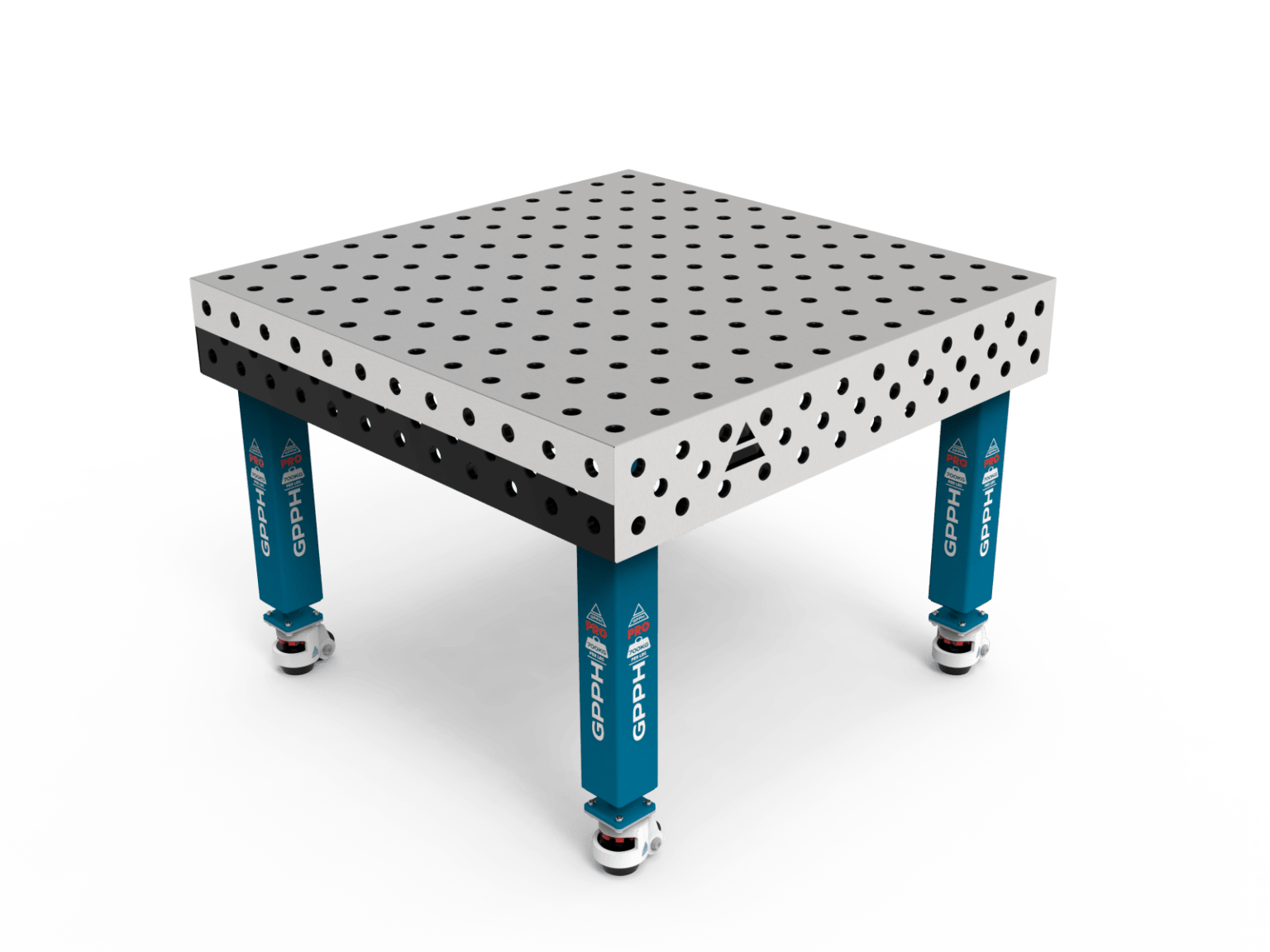

The PRO series stands out for its excellent load capacity, offering as much as 700 kg of load per leg. This series is an excellent choice for professional applications where precision and durability are key. The PRO tables are perfect for both manual and robotic welding, ensuring that structures are completed with the highest accuracy, without the need for correction.

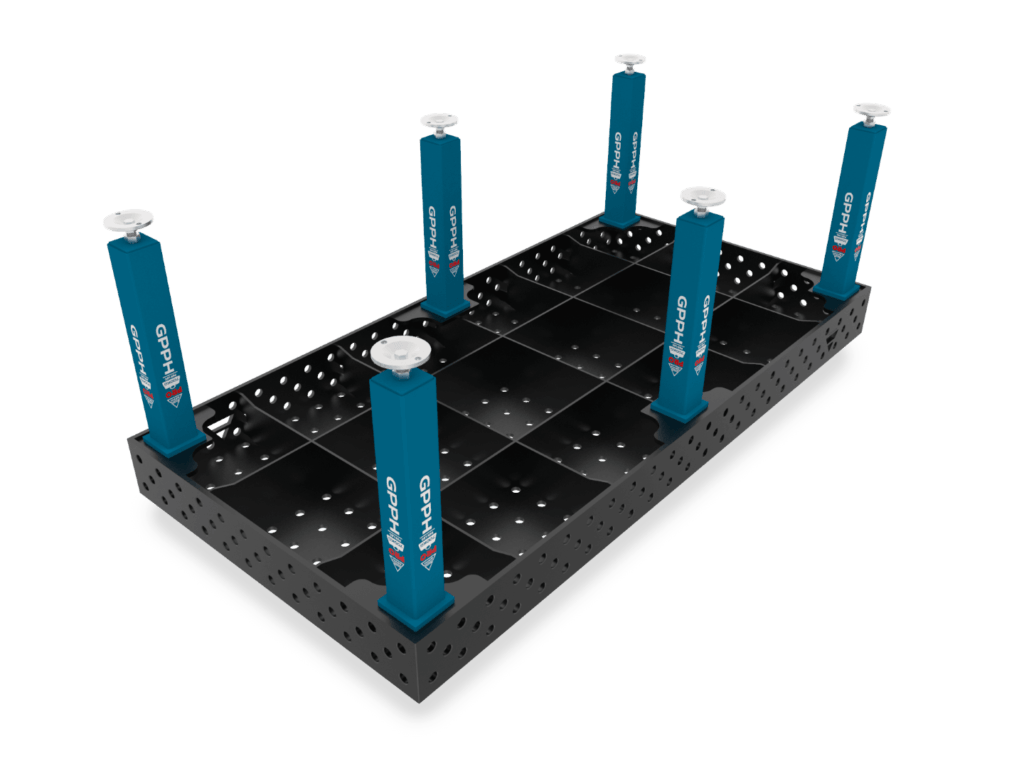

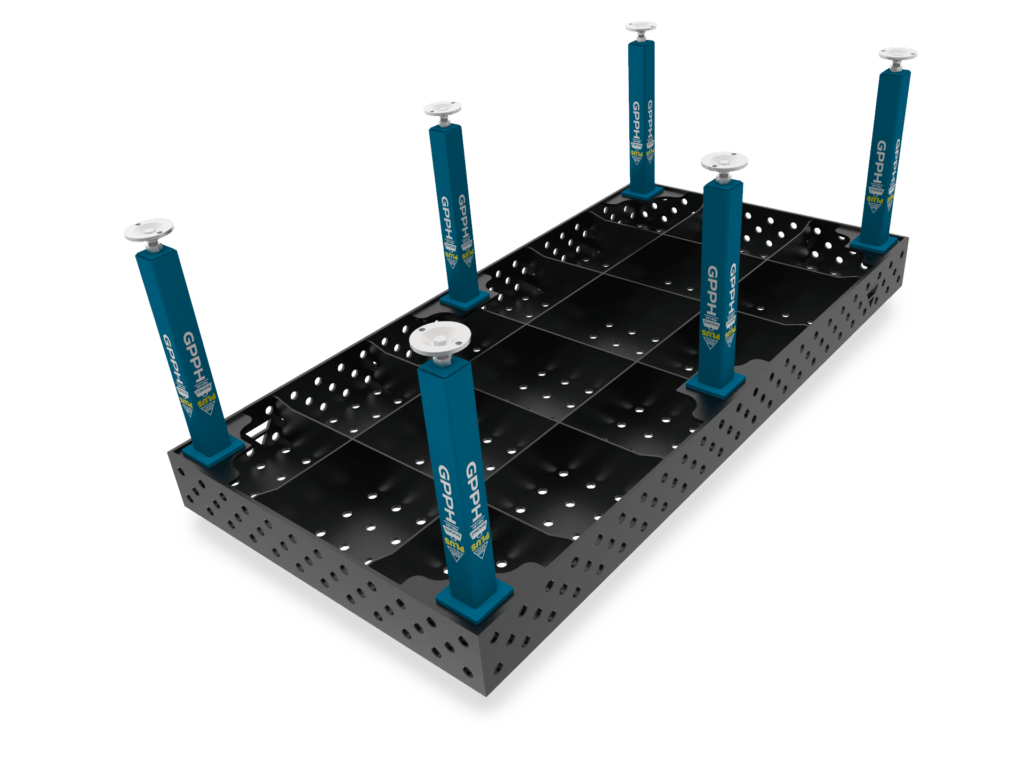

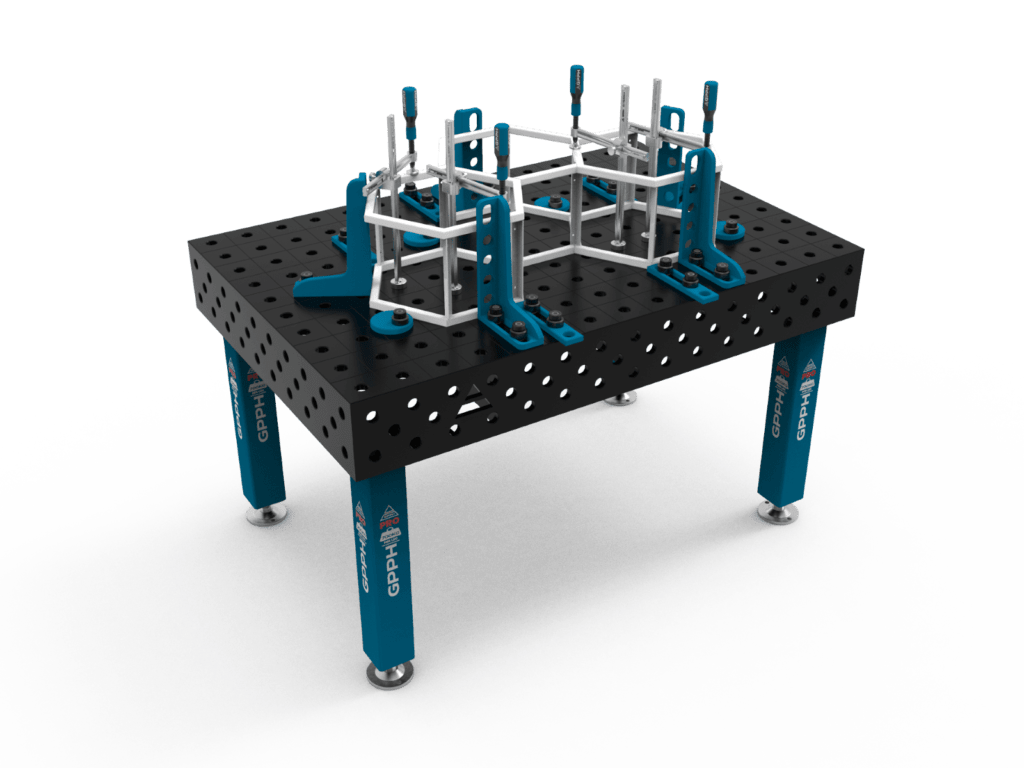

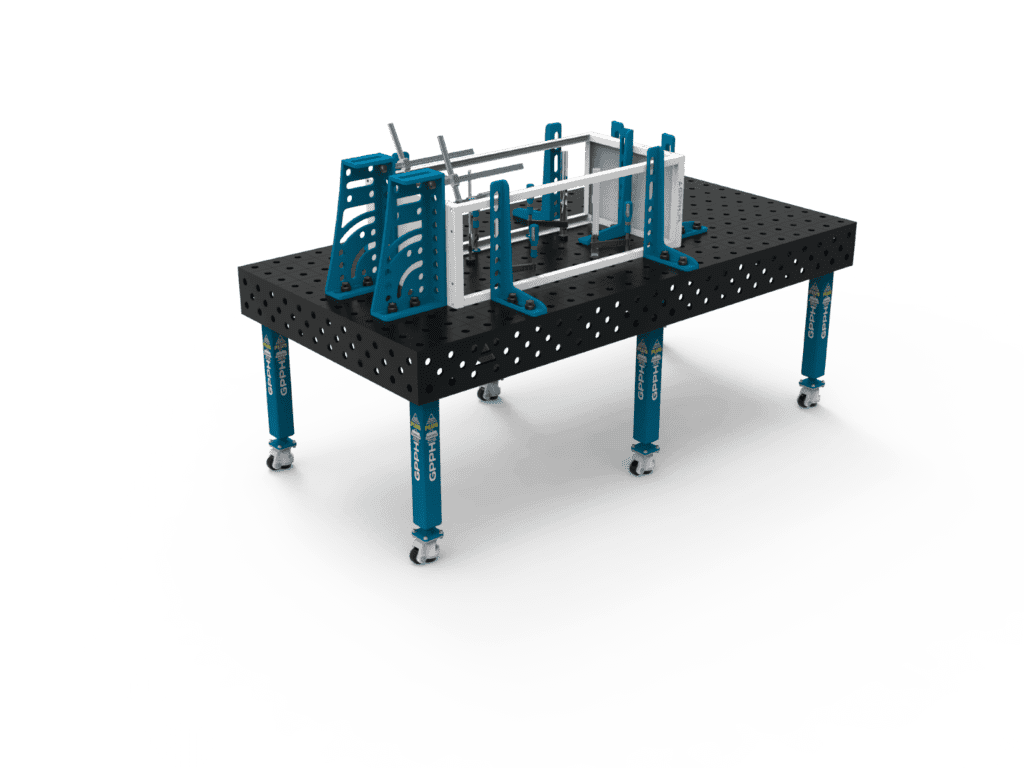

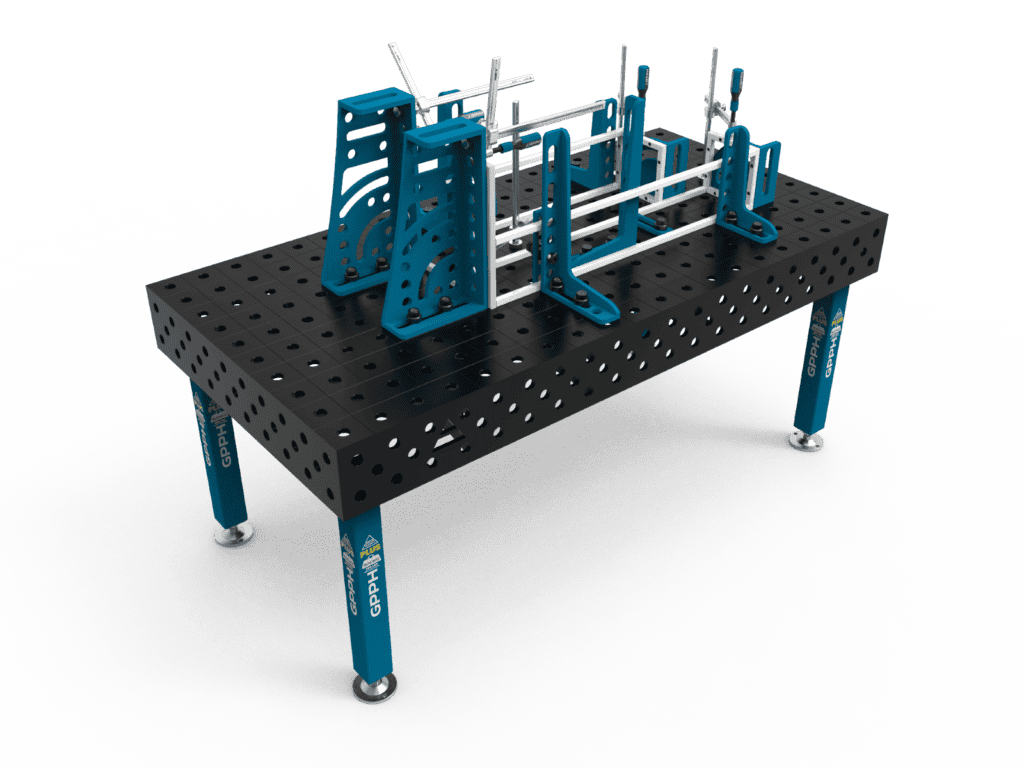

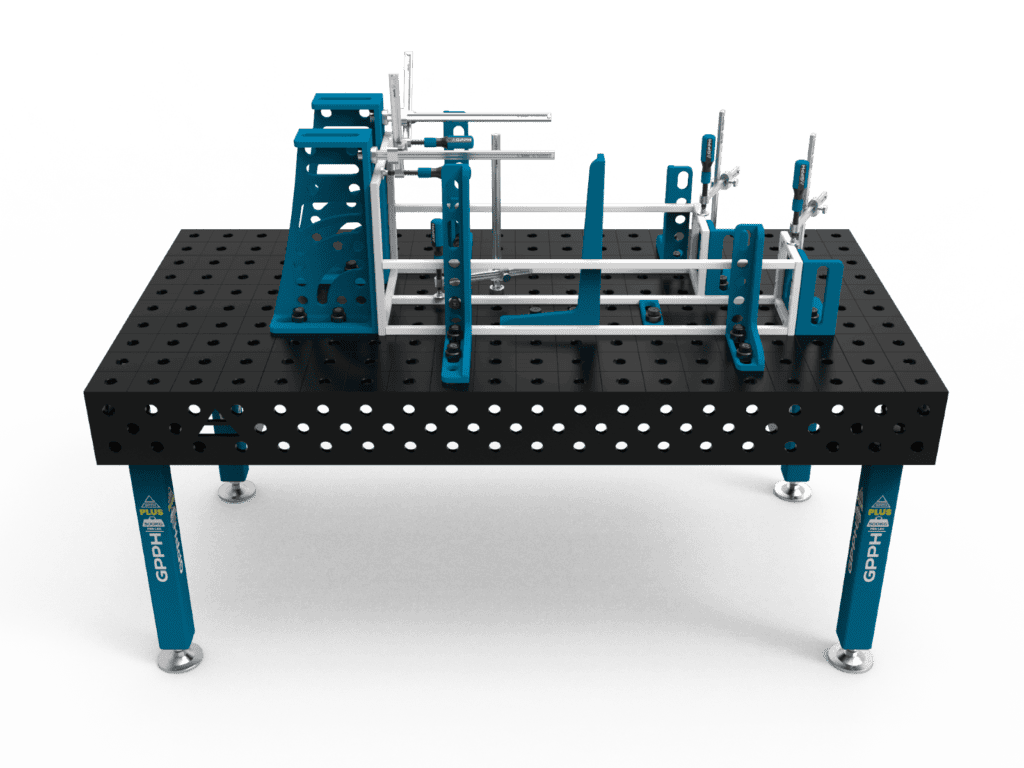

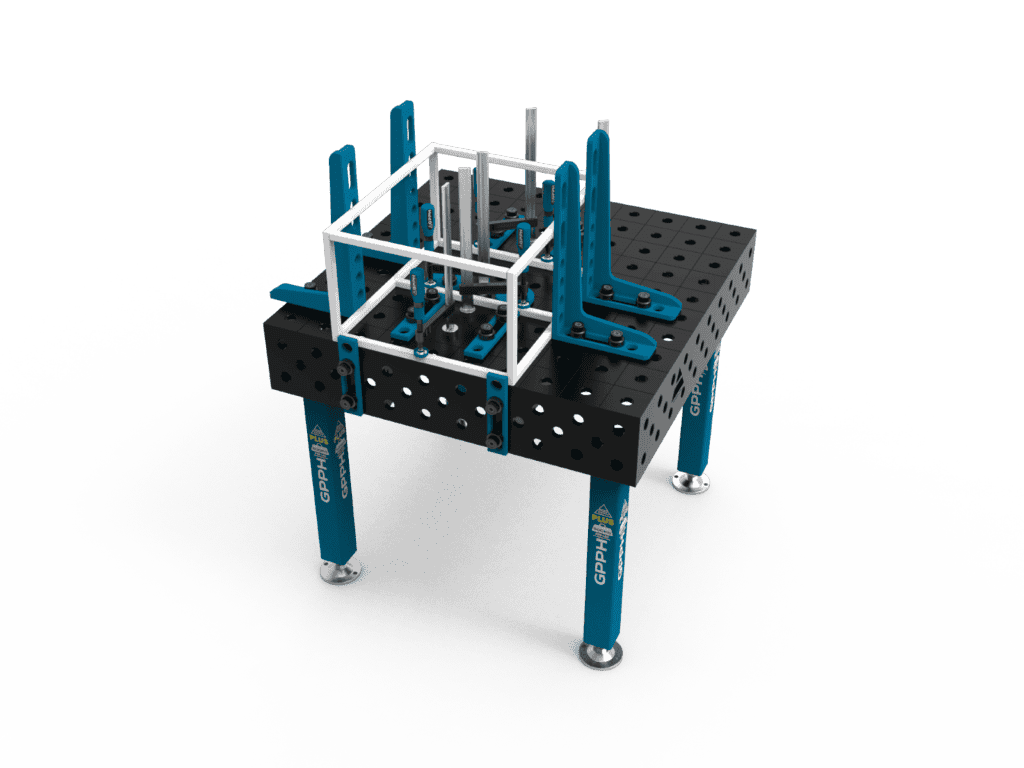

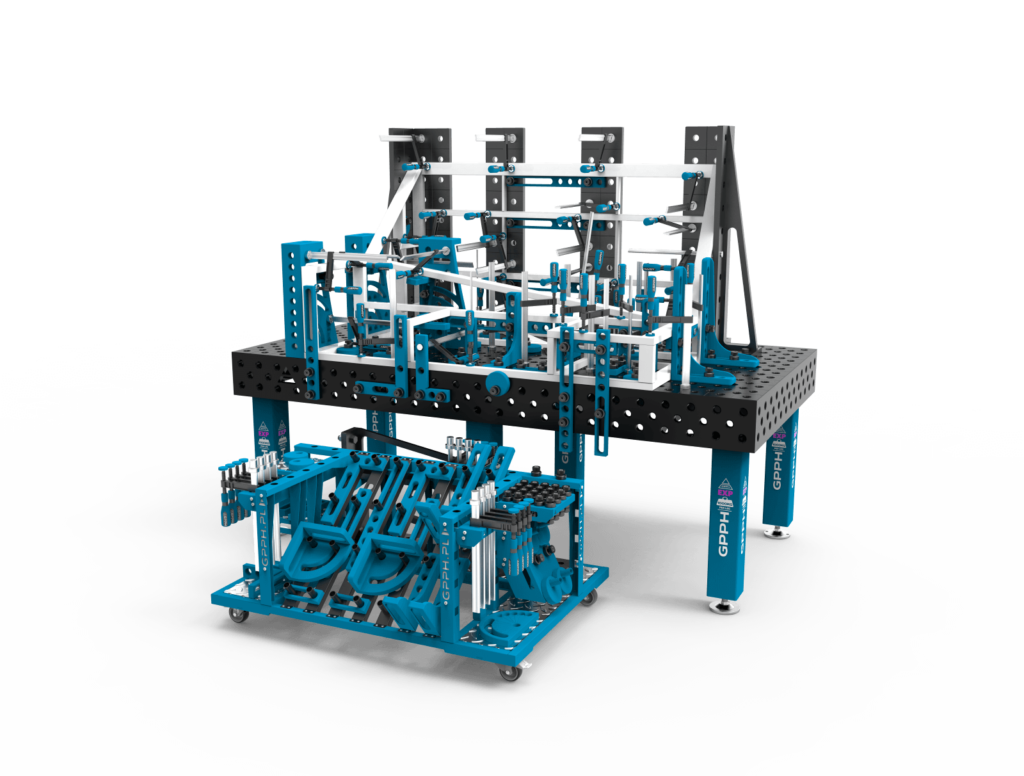

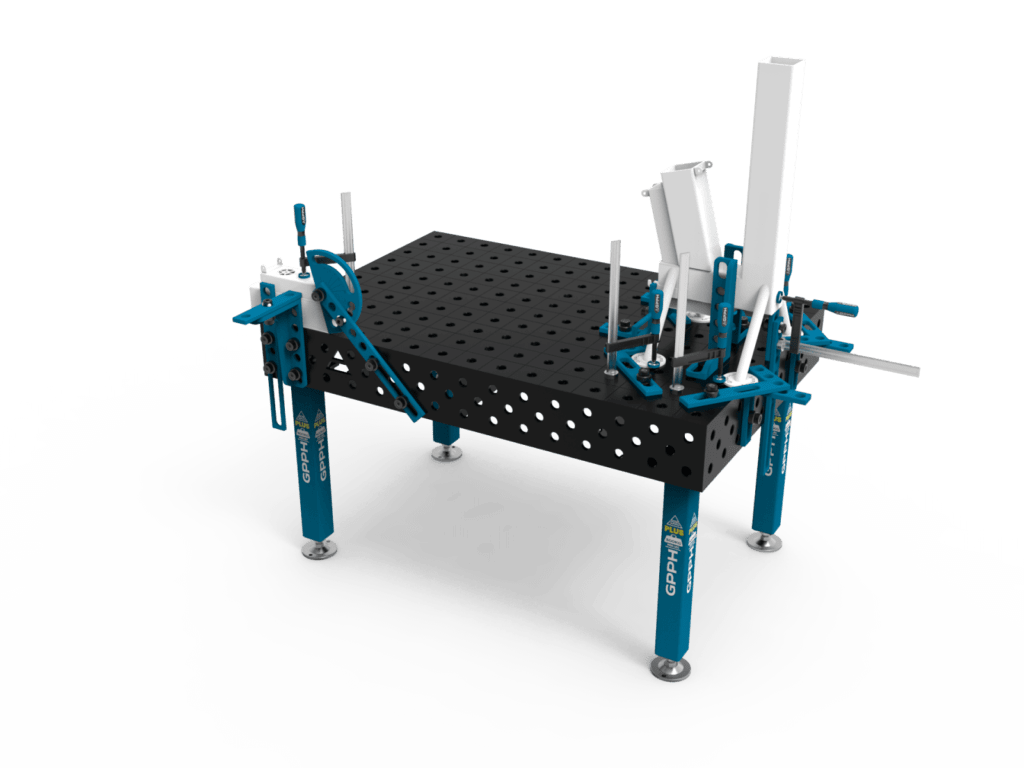

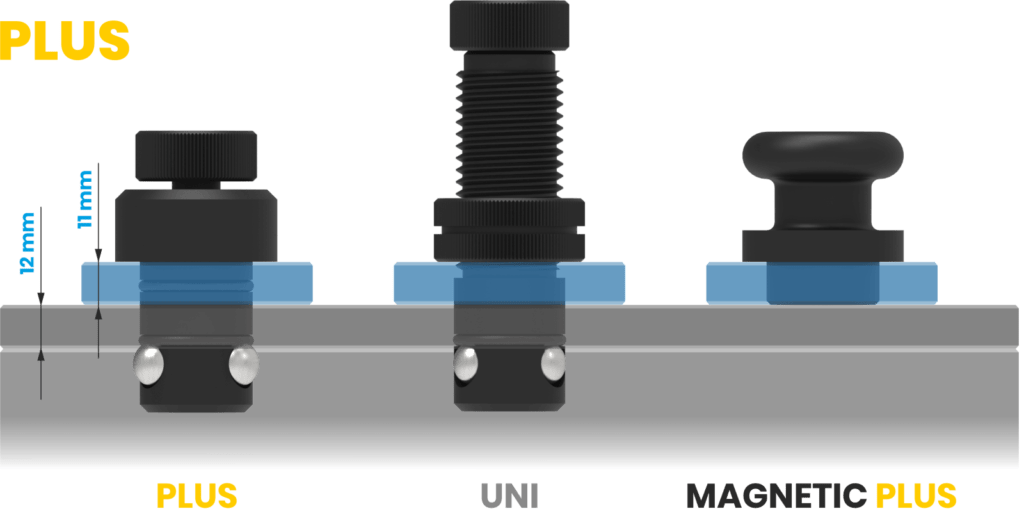

The PLUS series is the perfect combination of performance and versatility, offering a load capacity of 500 kg per leg. These tables are versatile and will work well in a variety of applications, giving you the flexibility to carry out a variety of welding jobs. The PLUS series is a great choice for both smaller workshops and larger productions where reliability and efficiency are key.

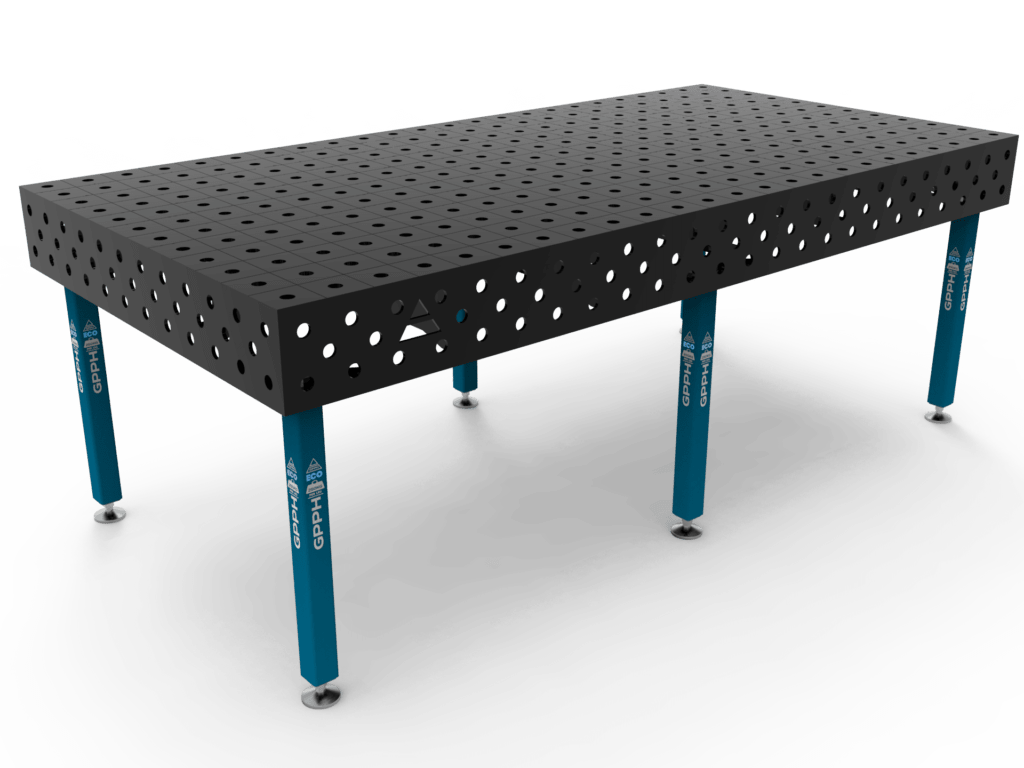

The ECO series is the ideal choice for those who need a robust table with a load capacity of 250 kg per leg, while maintaining an affordable price. The ECO series tables are ideal for smaller welding projects where precision is required and parts are not extremely heavy. This series offers excellent value for money, delivering performance and durability without overtaxing your budget.

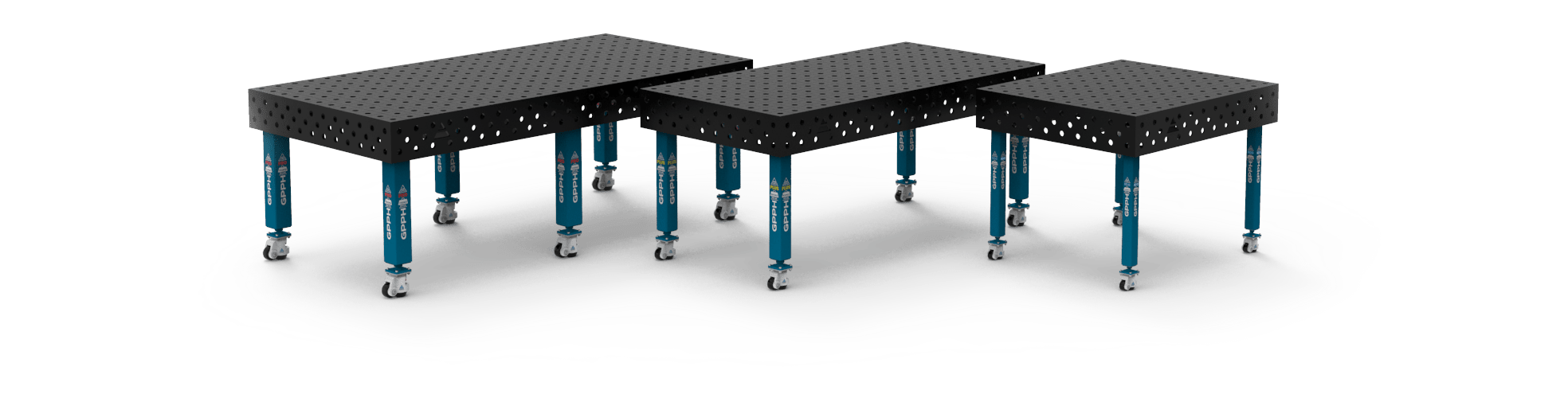

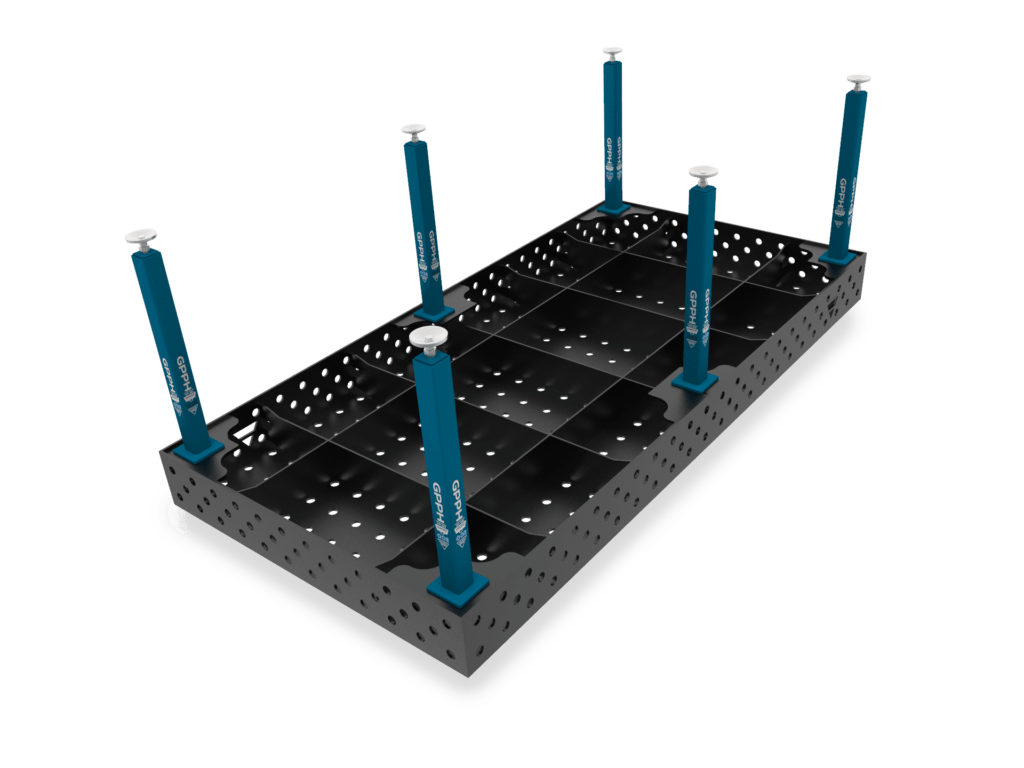

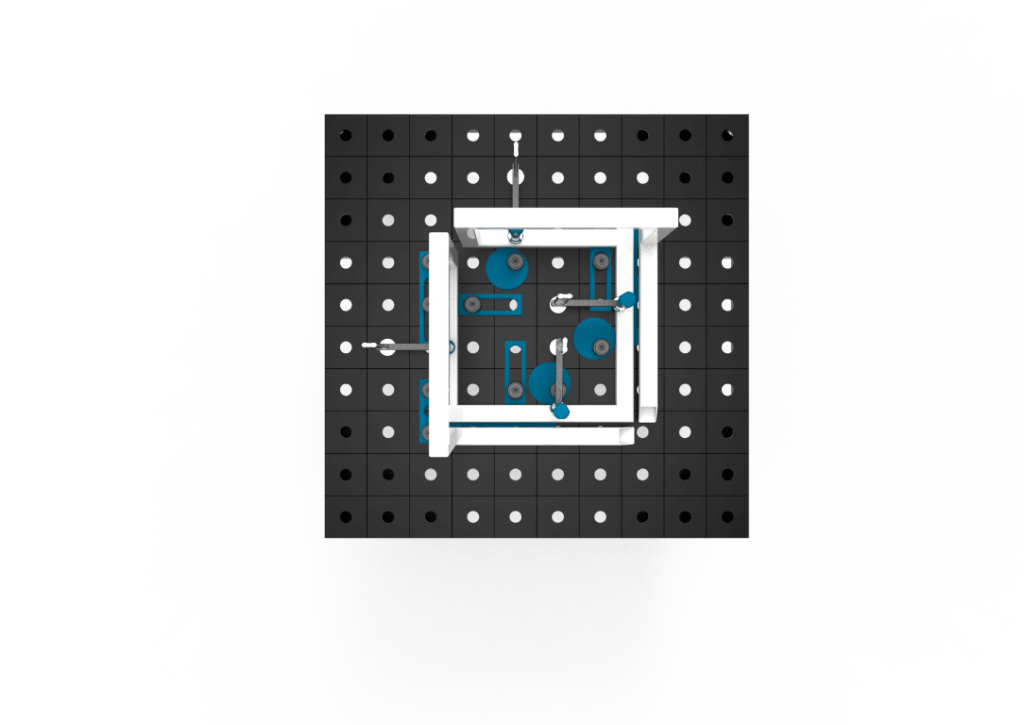

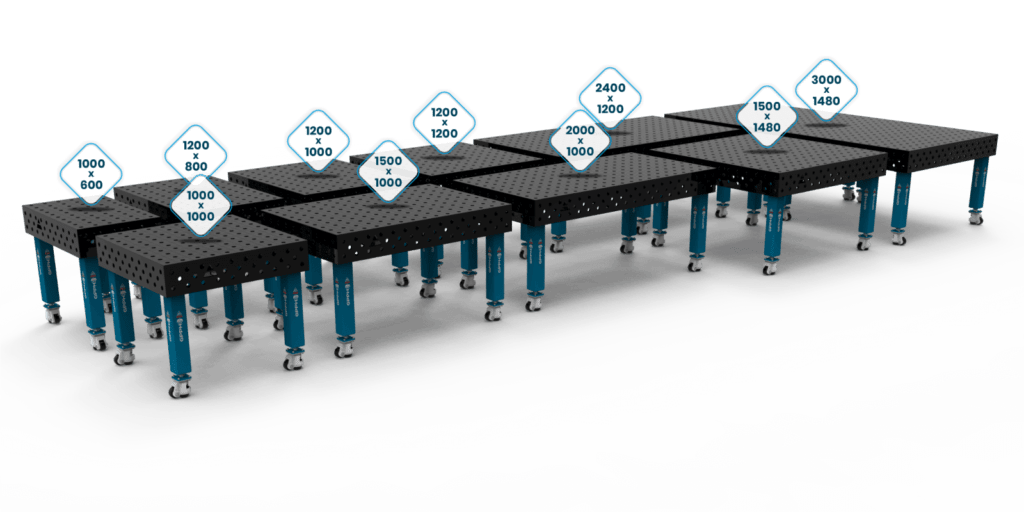

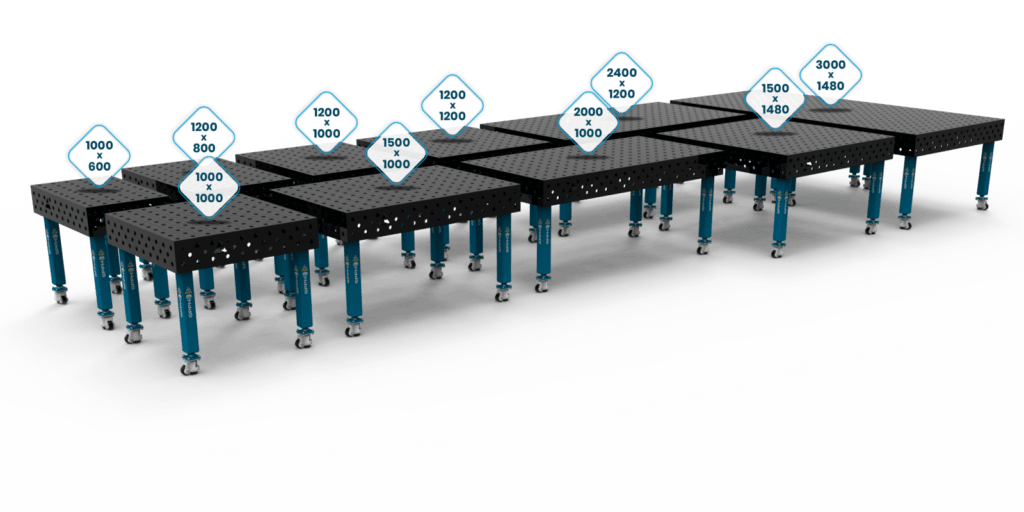

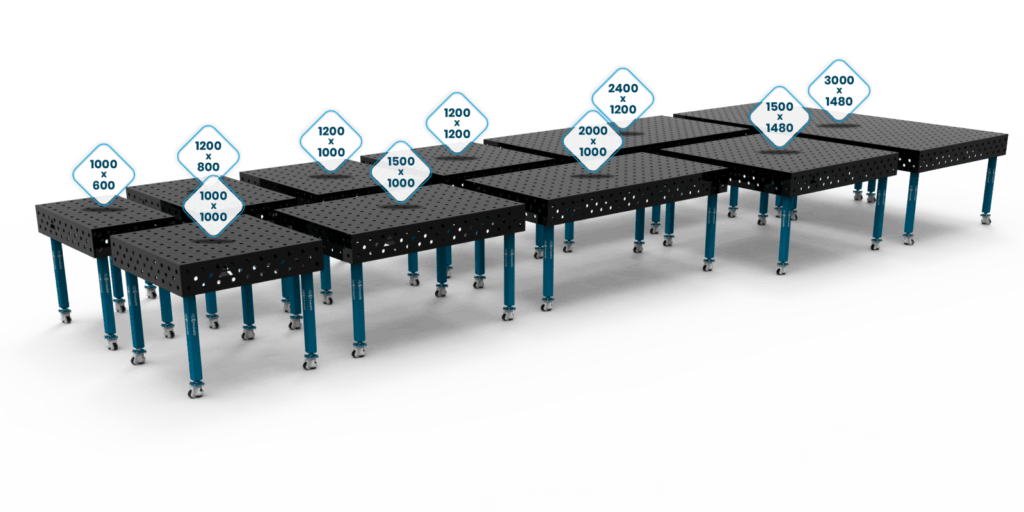

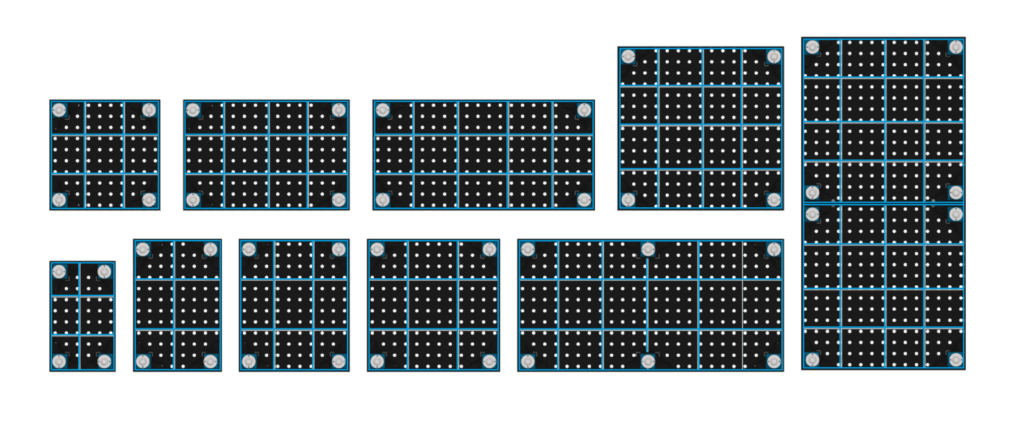

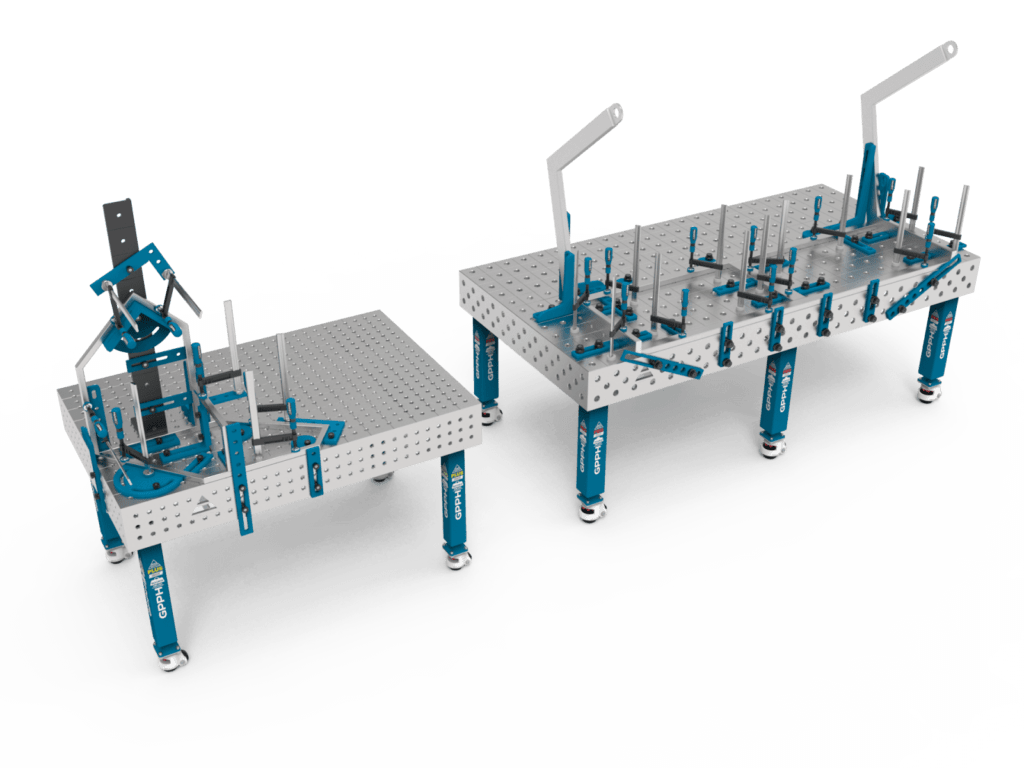

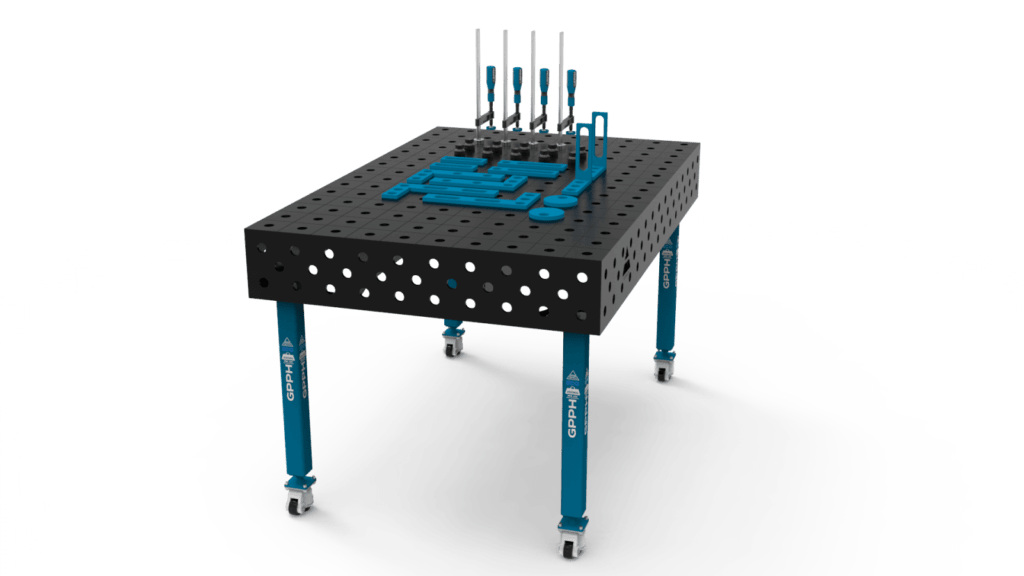

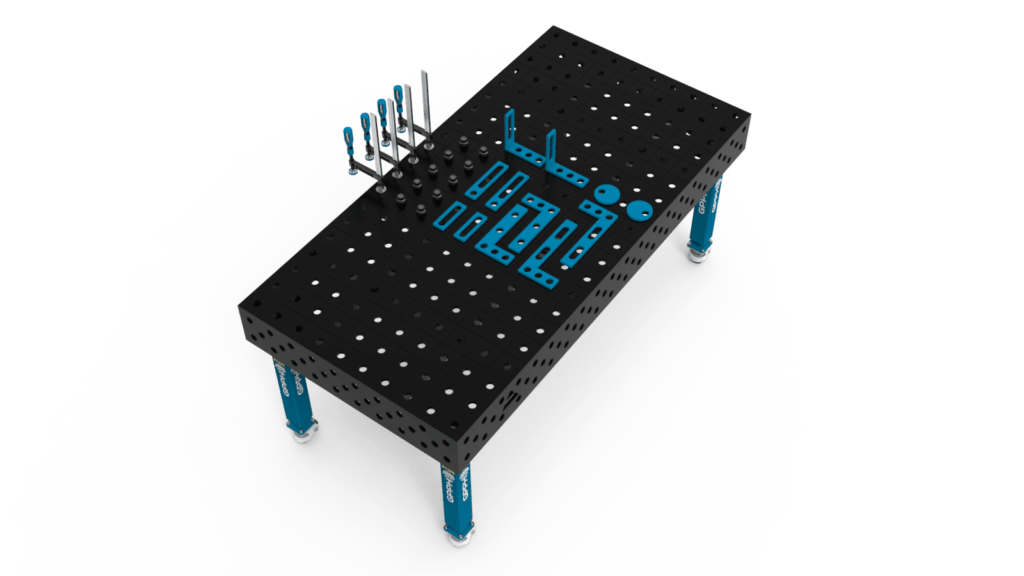

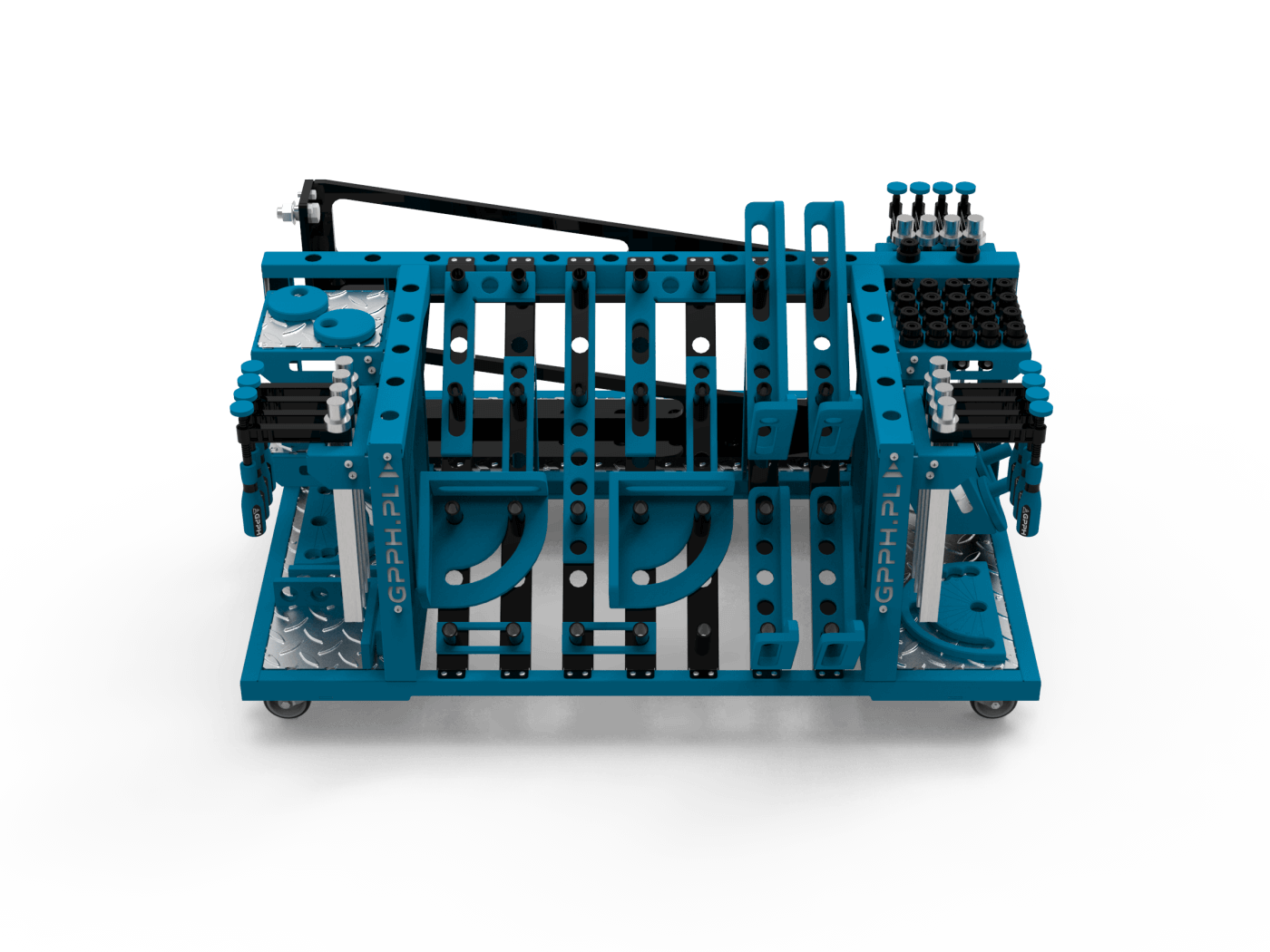

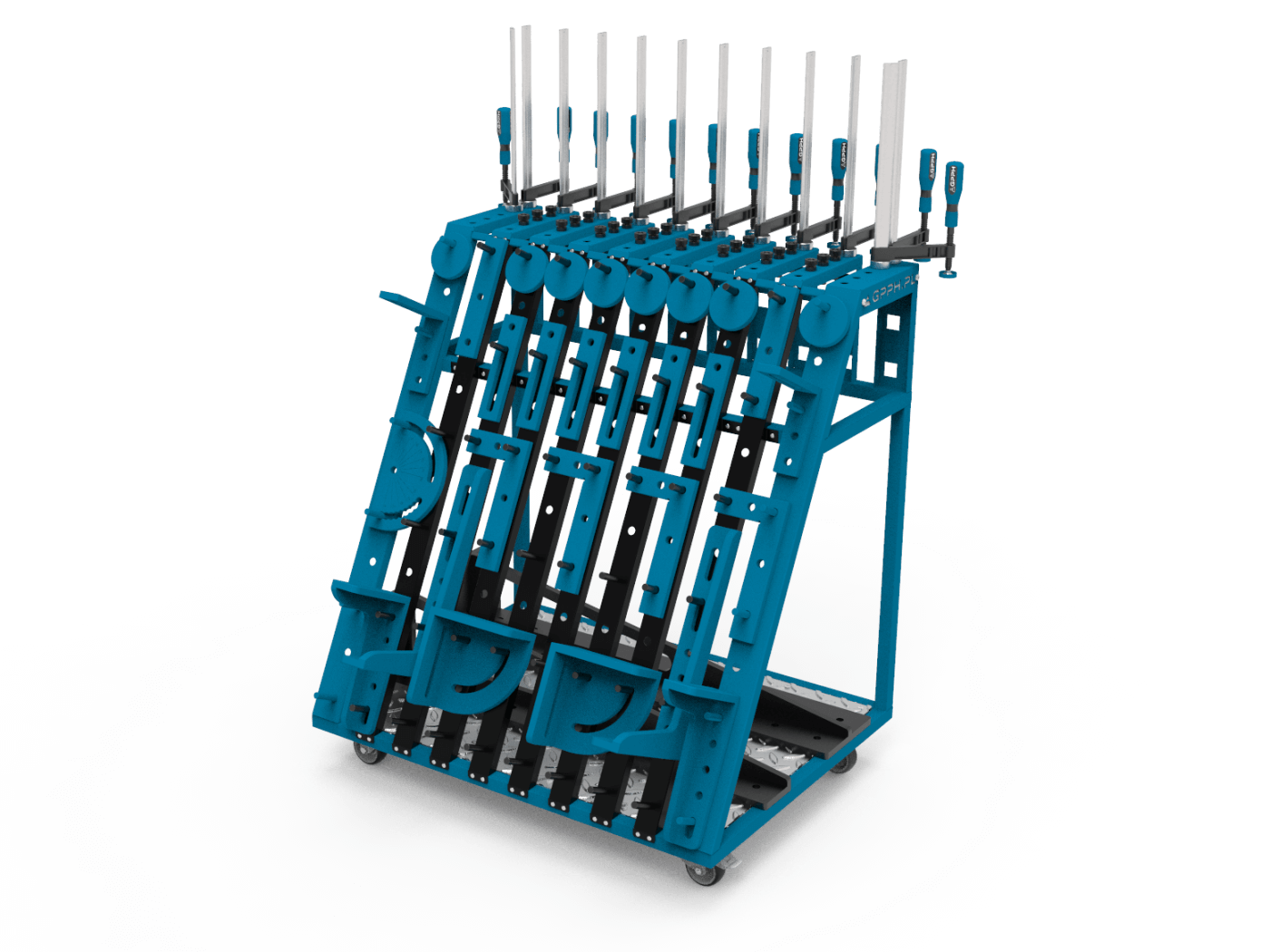

All welding tables in the EXPERT, PRO, PLUS and ECO series provide ergonomic and fast work, while maintaining the highest precision and repeatability of the constructions performed. In addition, versions are available with feet on feet or on wheels, giving you the freedom to choose which solution best suits your preferences and needs.

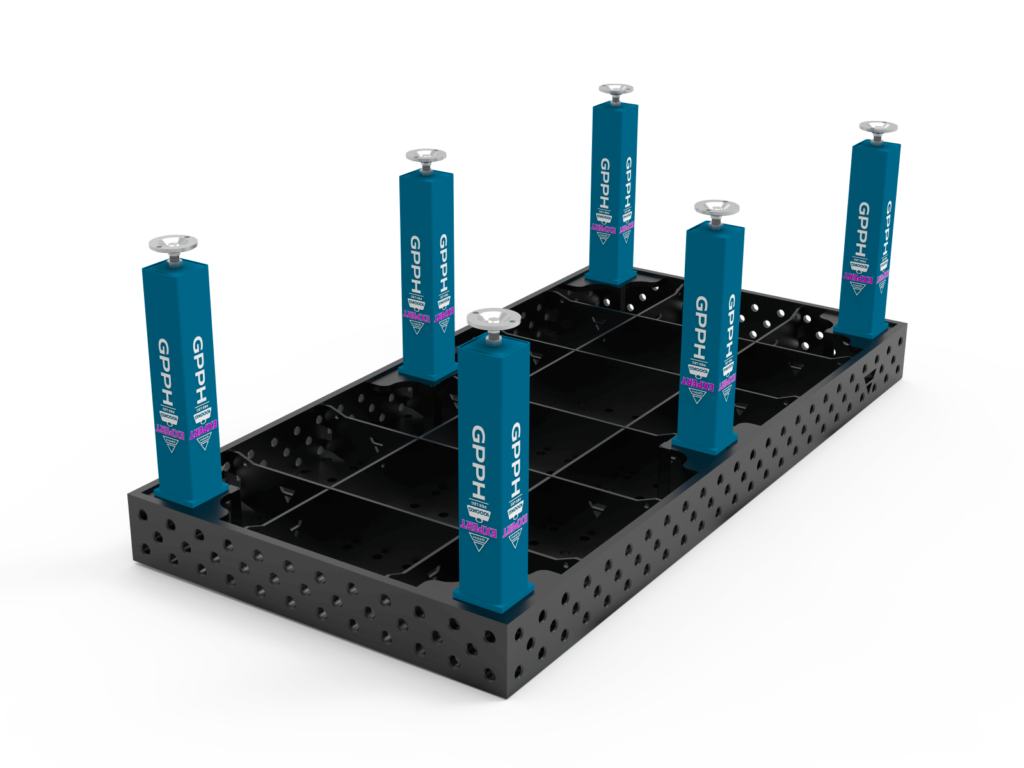

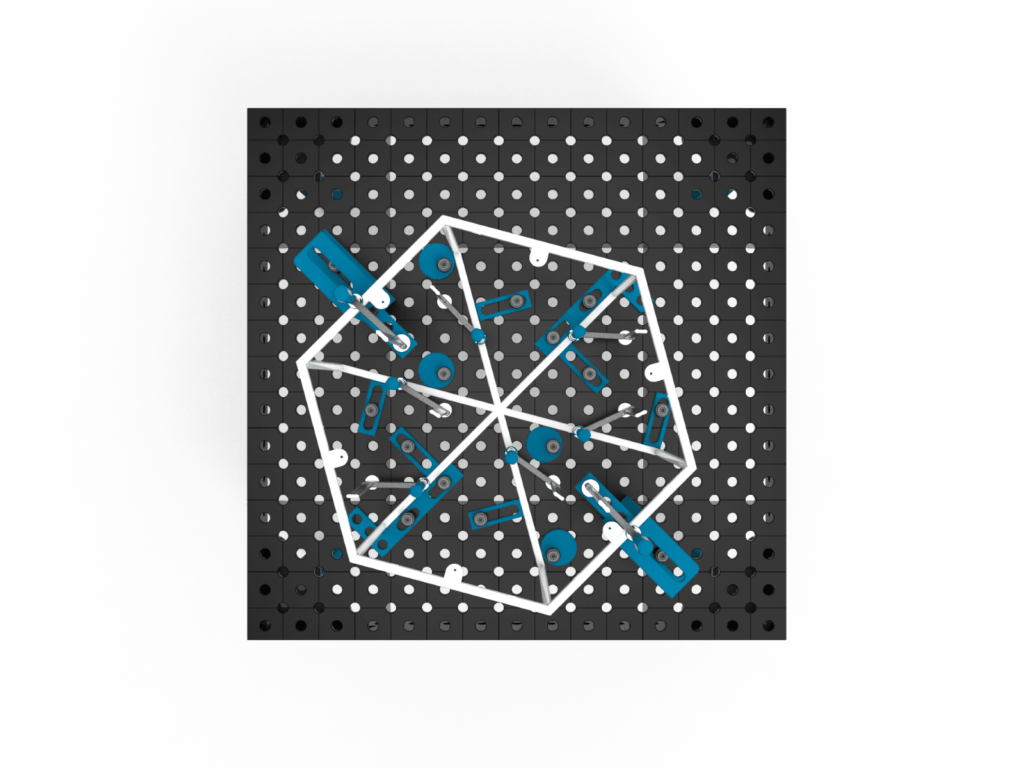

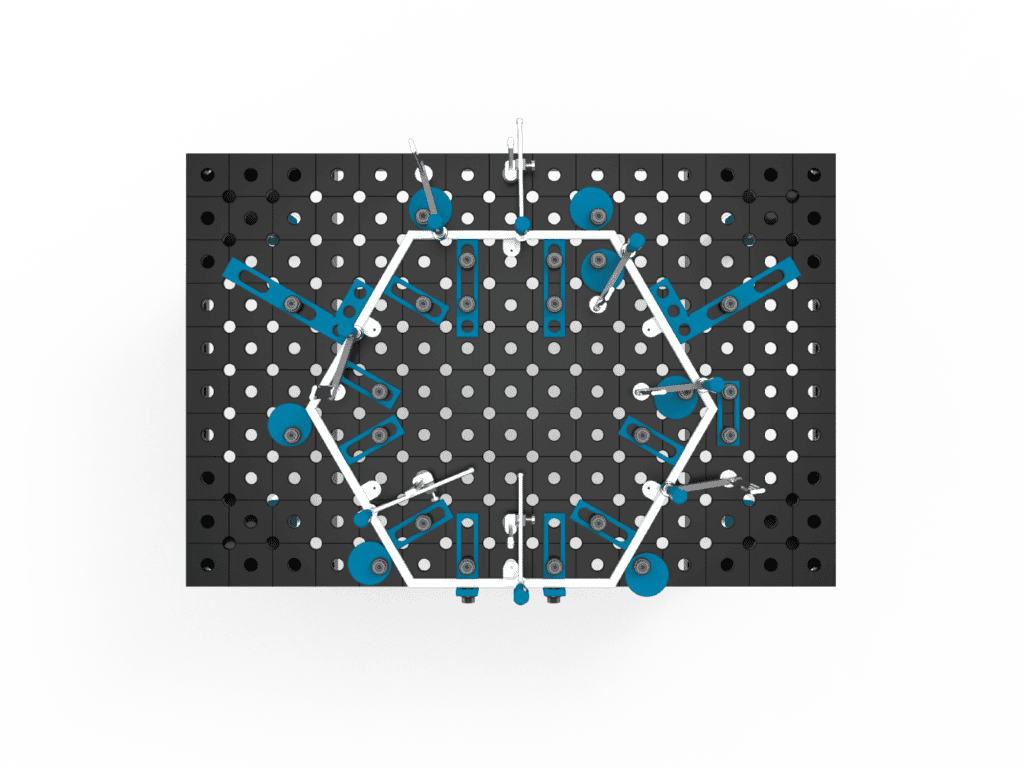

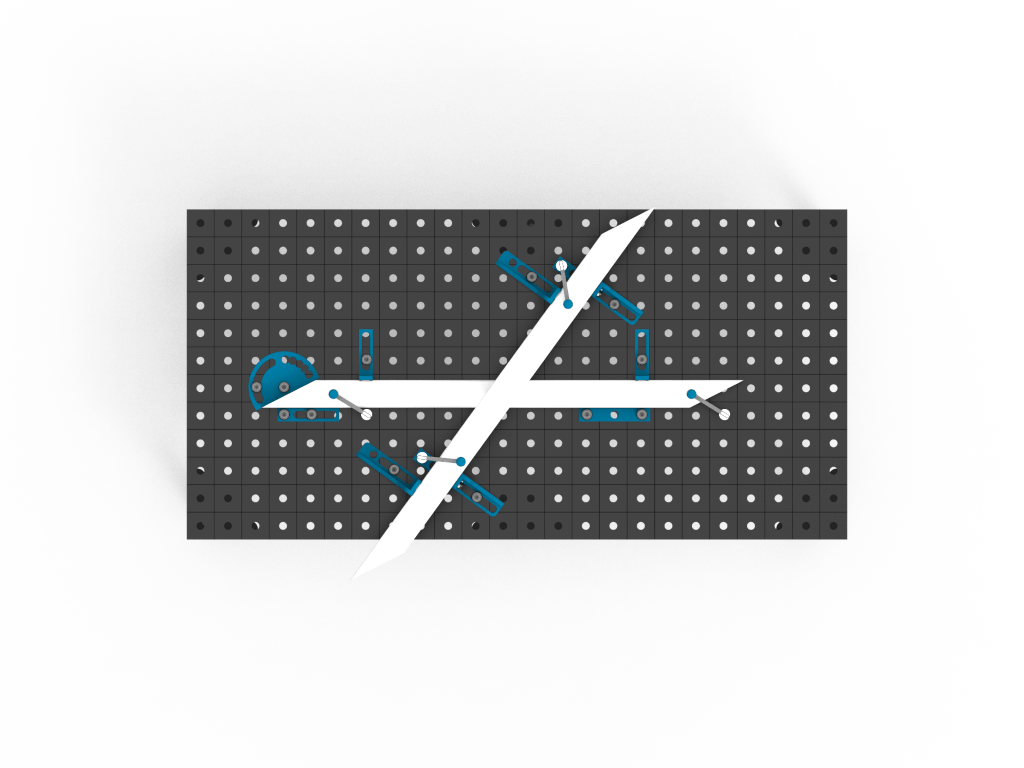

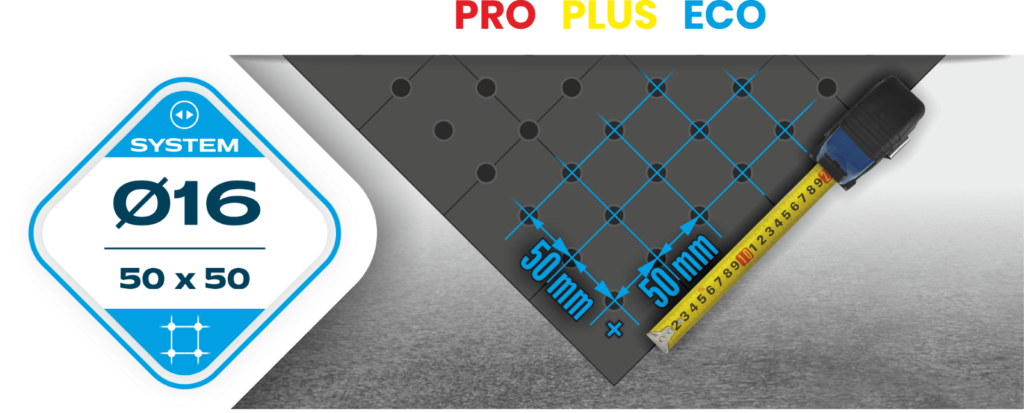

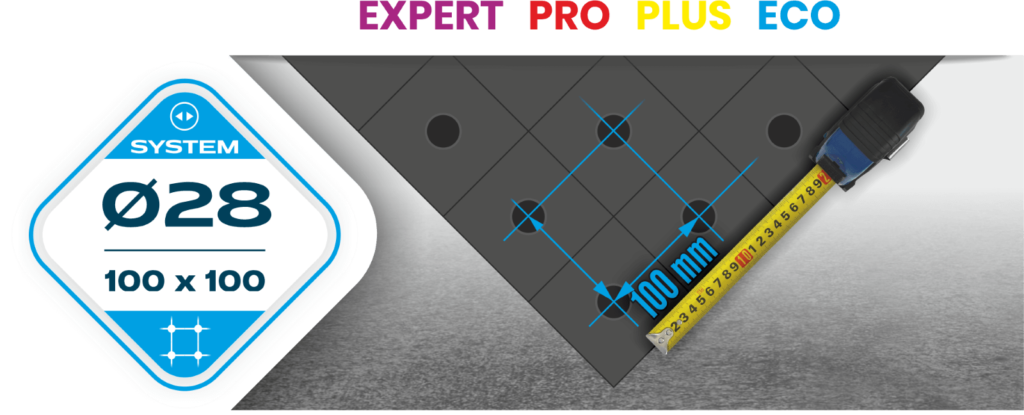

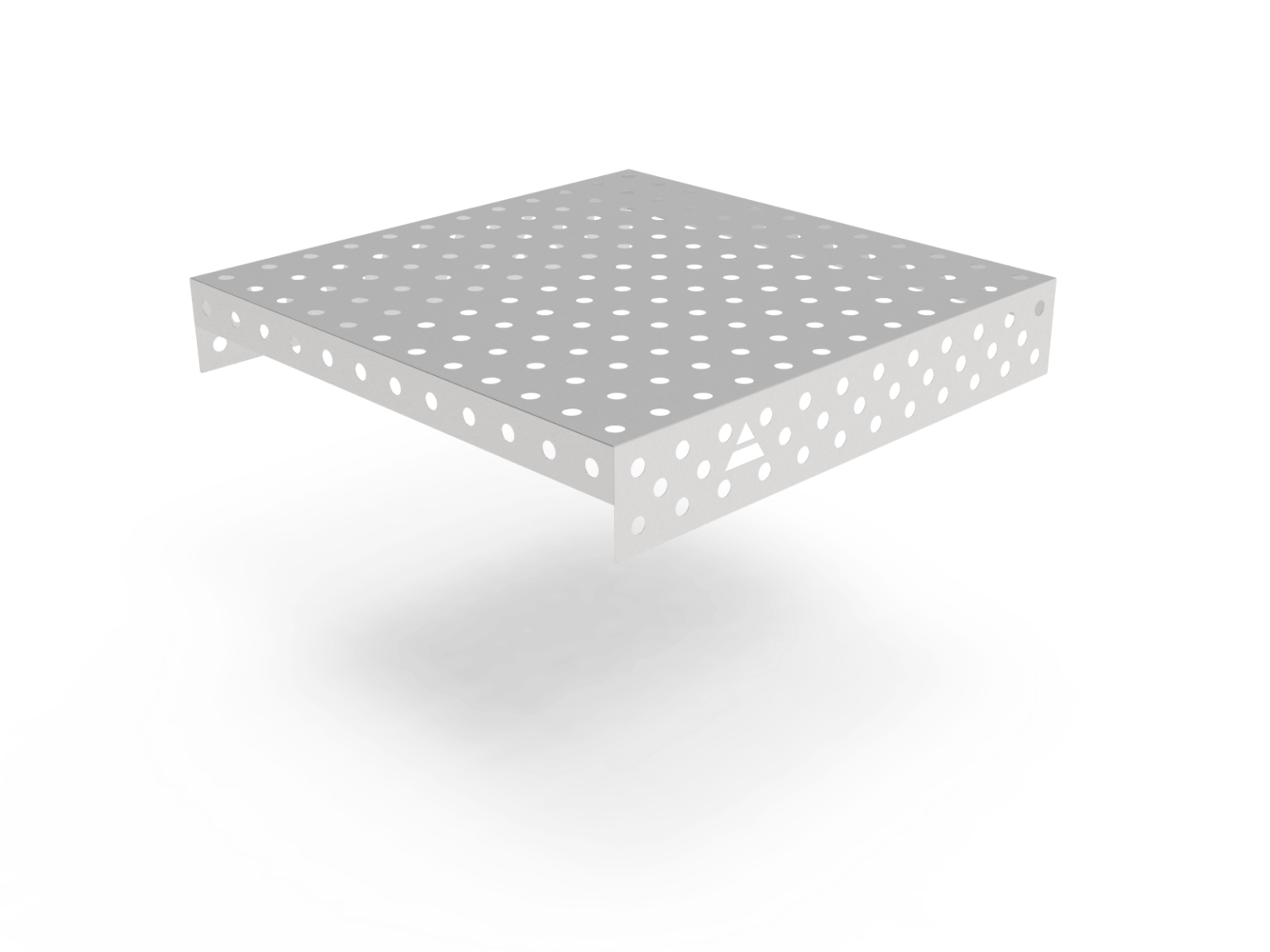

With different hole systems, i.e. fi 28 mm in 100x100 mm grid, fi 28 mm in diagonal grid, fi 16 mm in 100x100 mm grid, fi 16 mm in diagonal grid and fi 16 mm in 50x50 mm grid, our traditional GPPH welding tables will provide you with maximum versatility and flexibility in your work. Choose the right series and dimensions to enjoy the reliability and quality of our welding tables.