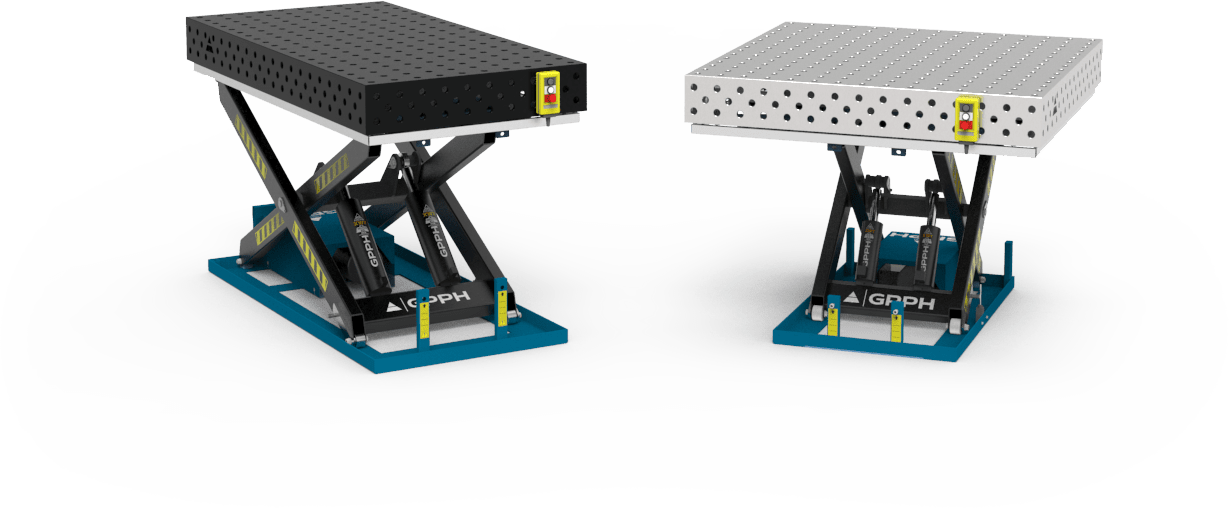

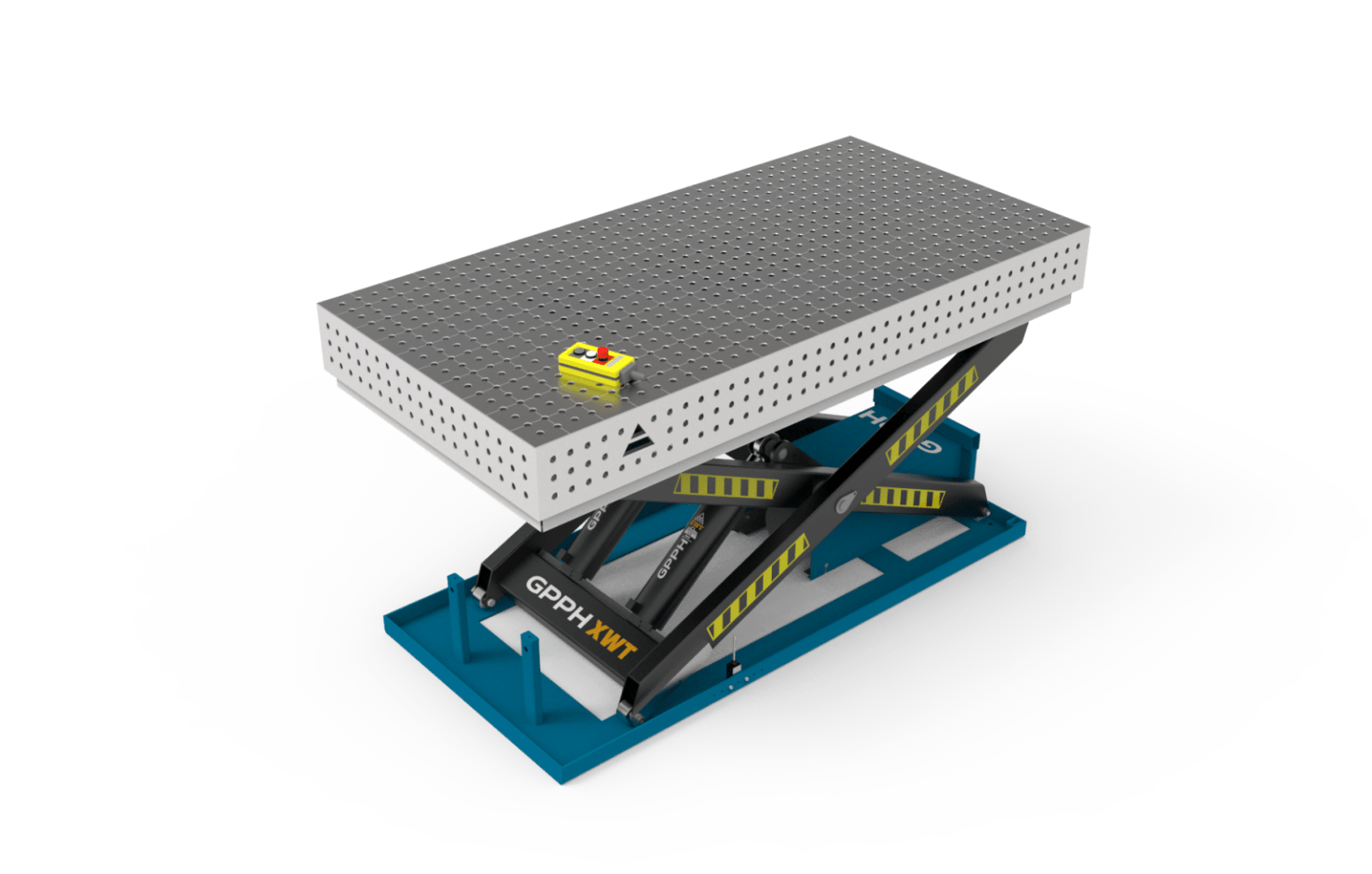

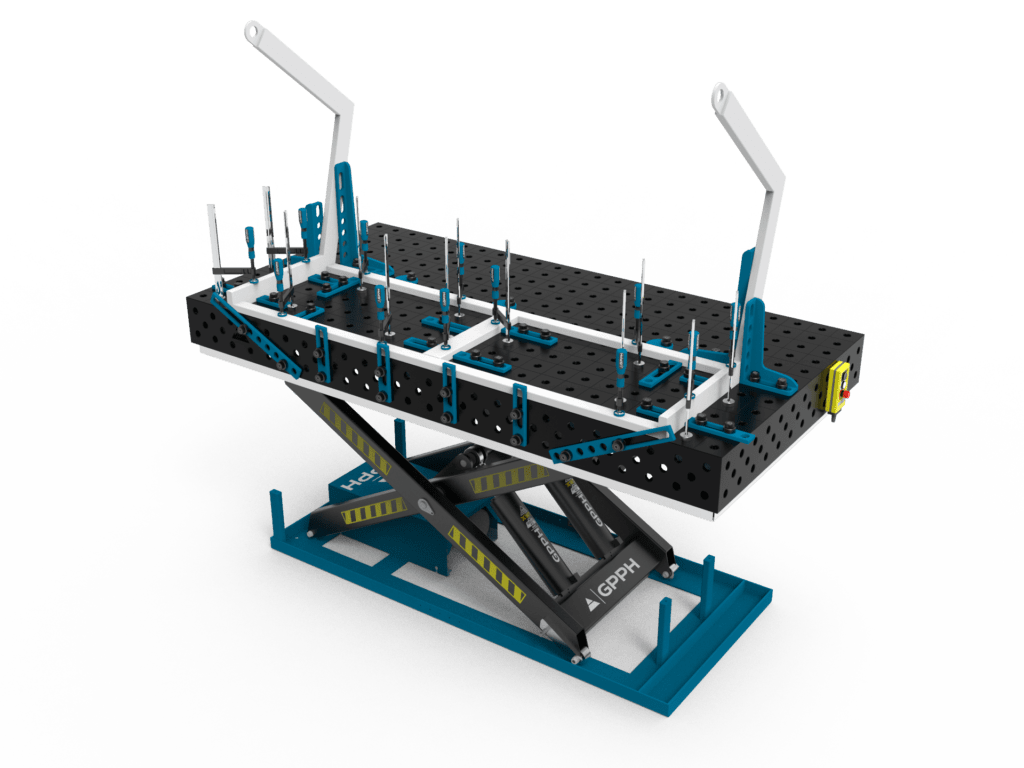

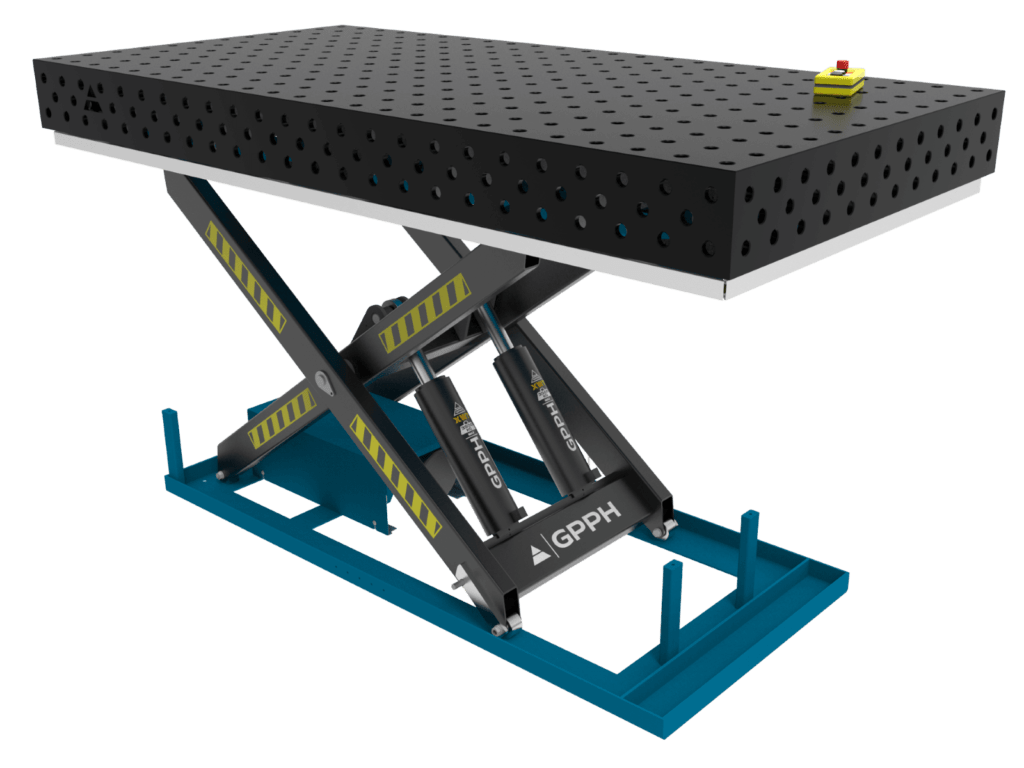

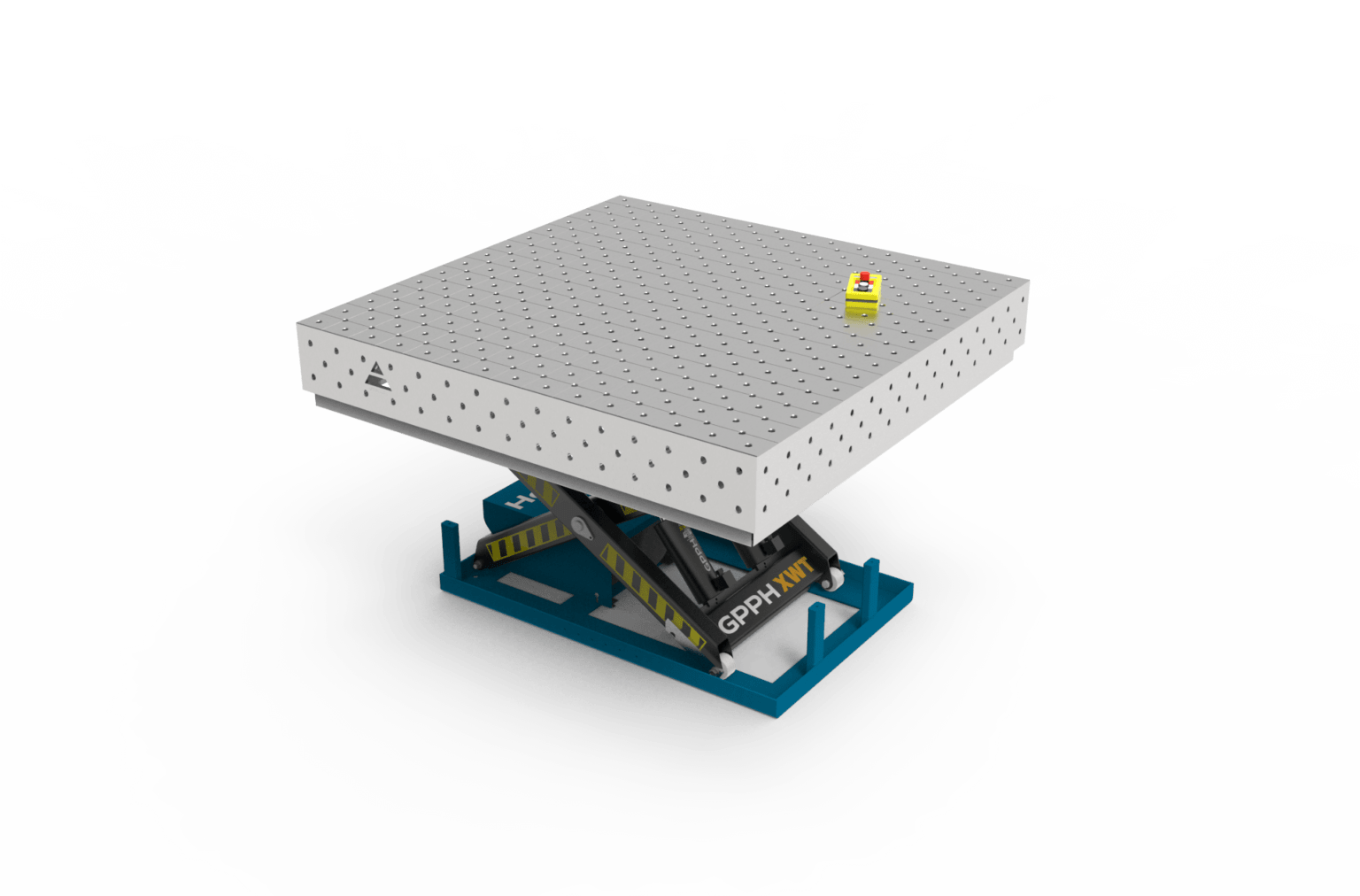

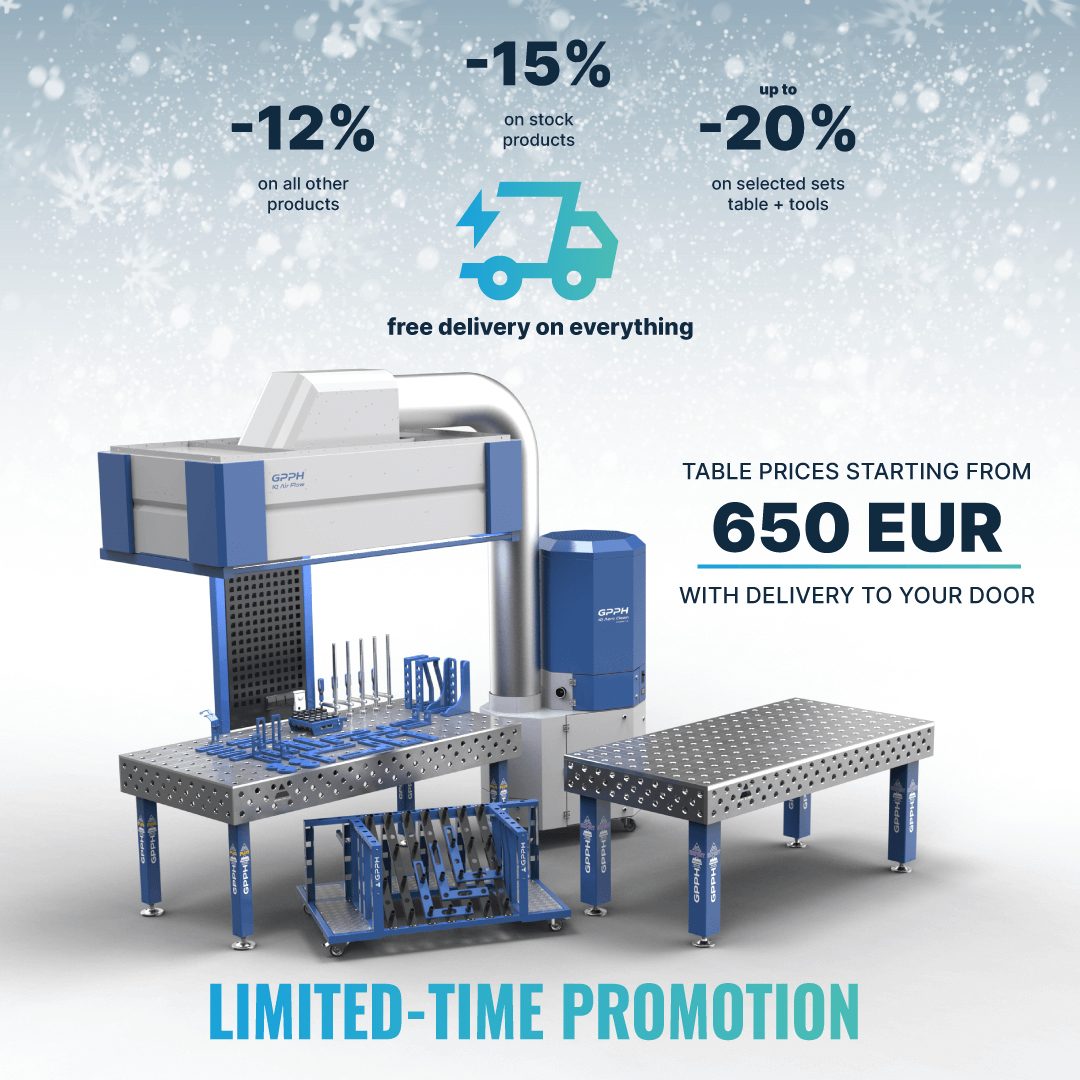

Welding tables with a hydraulic lifting system have many advantages. Above all, they eliminate the need to manually adjust the height of the table top, which significantly speeds up the work process and saves time. You can adjust the height of the table to suit any task, ensuring you have the optimum conditions for precision welding.

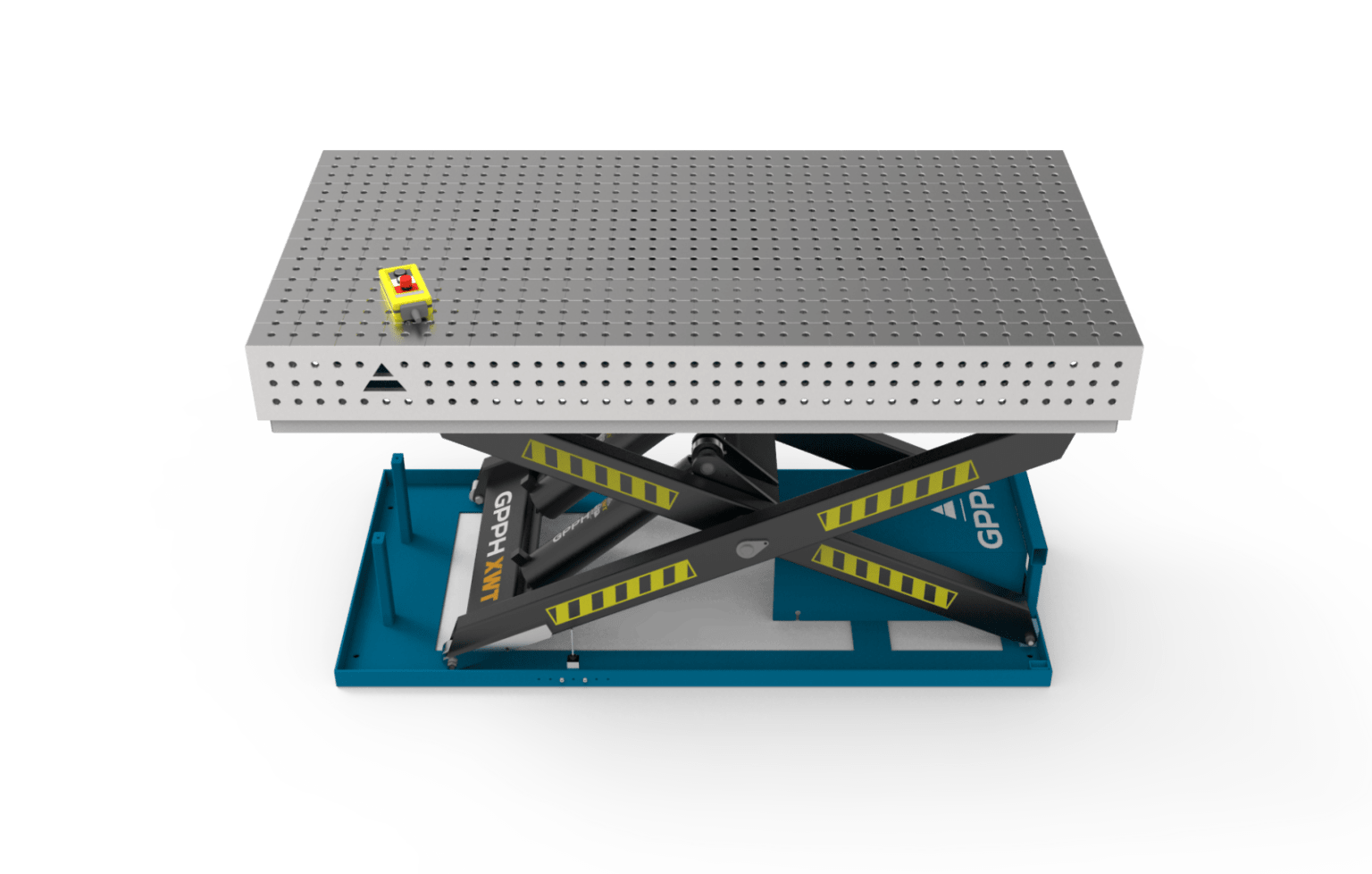

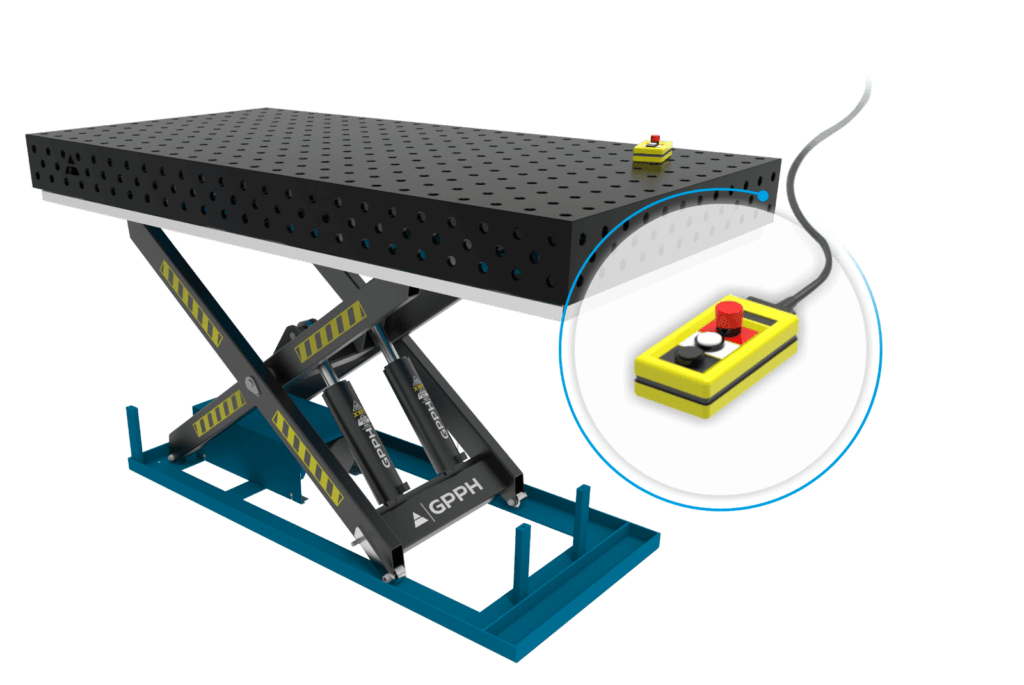

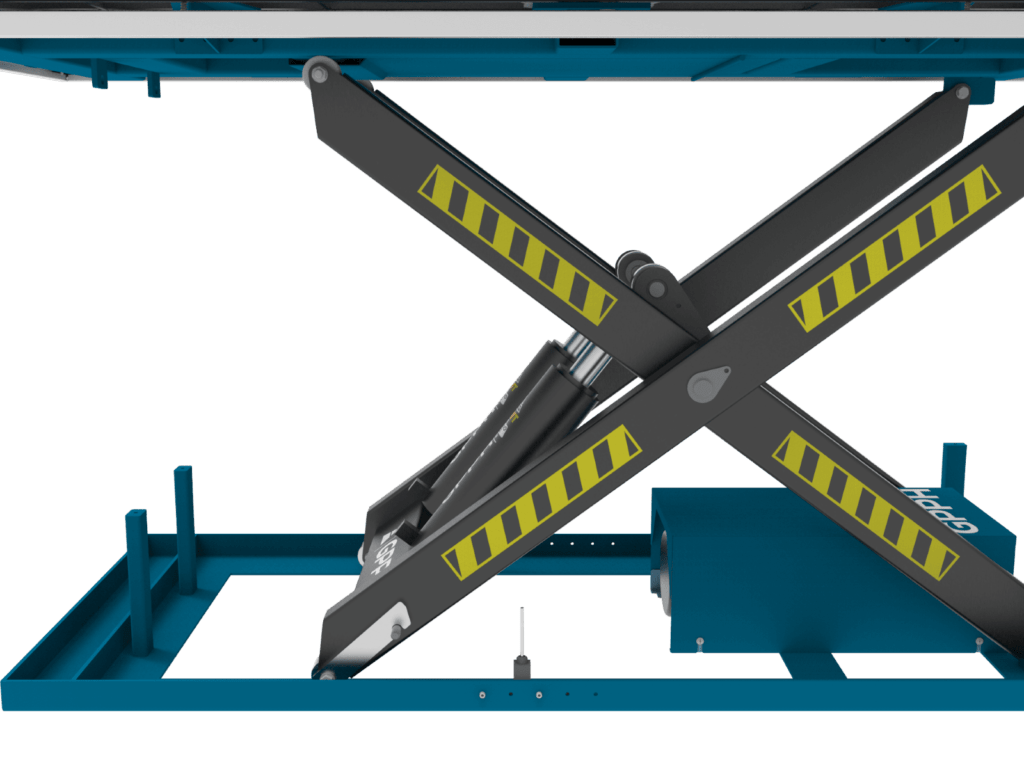

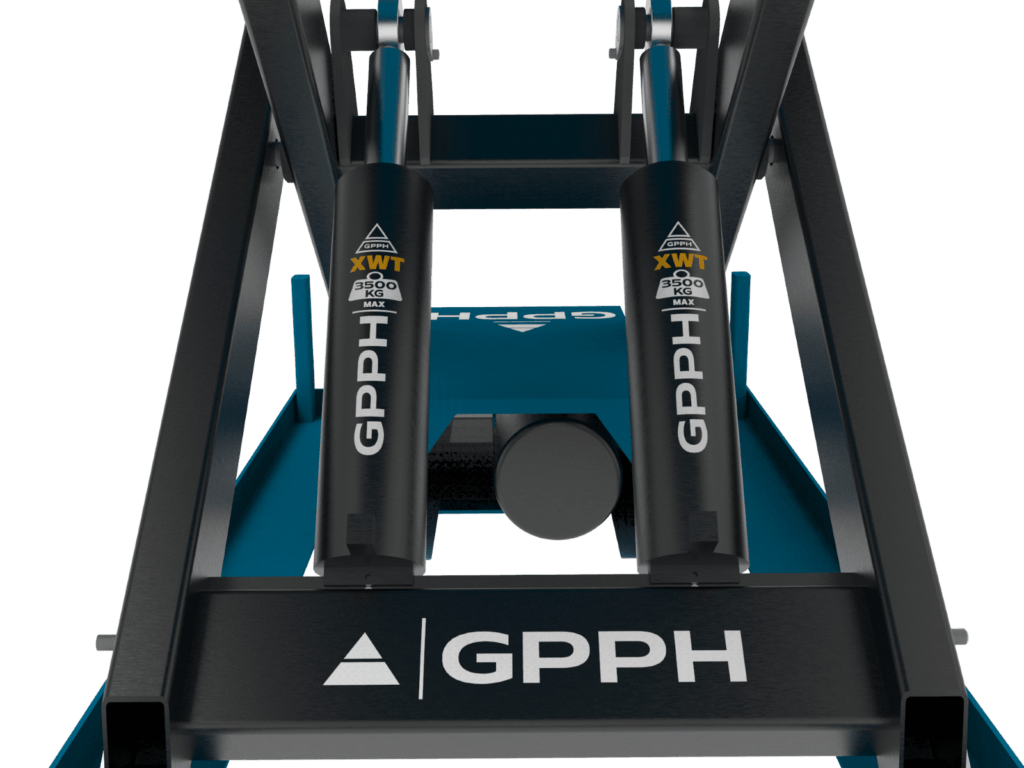

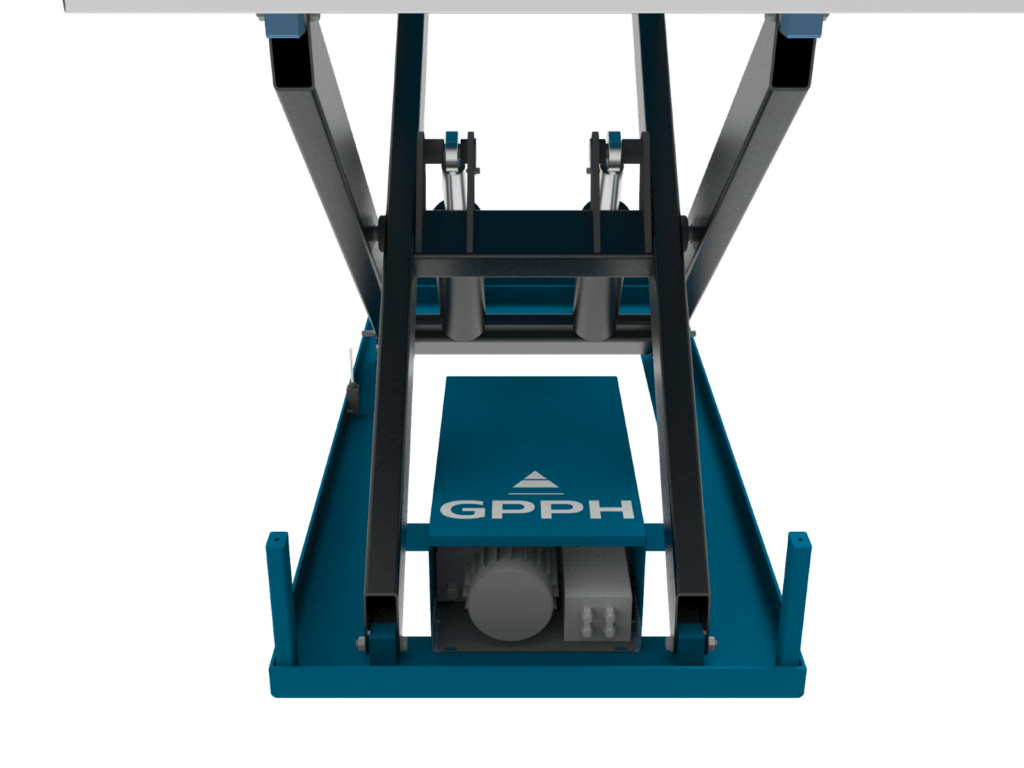

The hydraulic lifting system is also extremely safe and reliable. Thanks to overload and safety valves, the risk of damage to the table or injury to the user is minimised. Limit switches provide additional safety, protecting against accidental accidents during lifting and lowering operations of the table top.

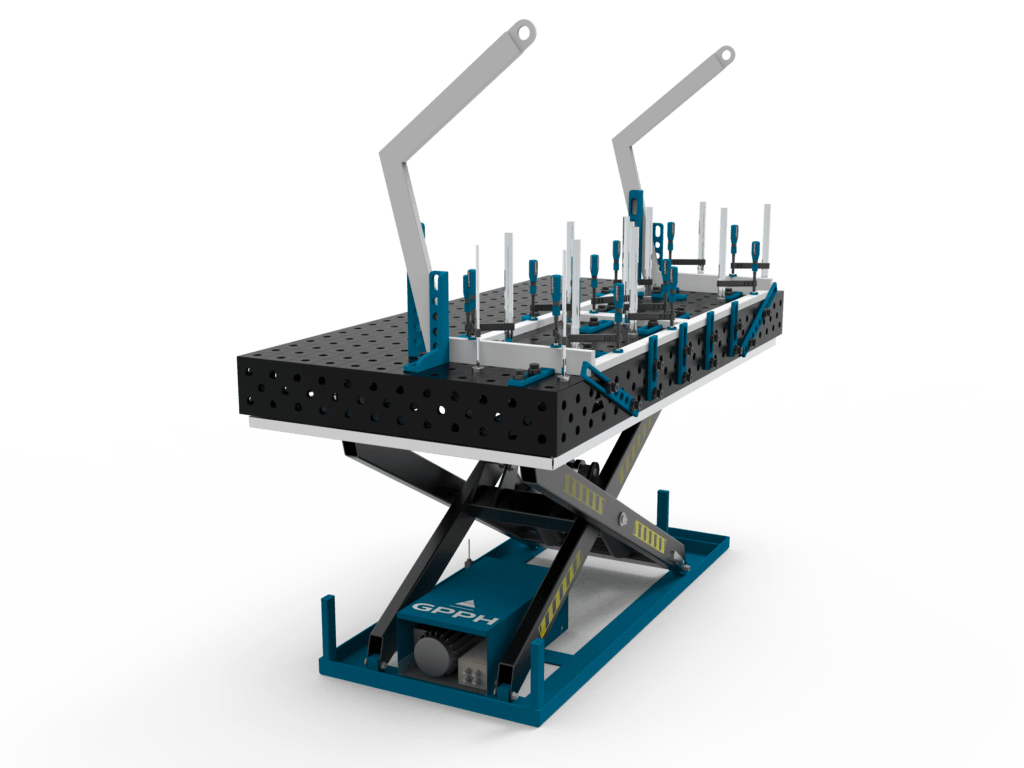

There are many benefits to using GPPH welding tables with a hydraulic lifting system. They provide ergonomic working conditions by eliminating the need for manual height adjustment. This is not only convenient, but also reduces fatigue during prolonged welding tasks. In addition, the ability to fine-tune the height of the table top affects the quality and accuracy of welding. This allows you to achieve excellent results, especially on jobs that require special attention to detail.

GPPH welding tables with hydraulic lifting system are the perfect choice for professional welders who value comfort, safety and excellent quality of the work performed. It is an advanced solution that makes the welding process much easier and more efficient, ensuring satisfactory results of the work performed.