5 skills that distinguish a good welder – and how to develop them in everyday work

In the world of welding, it is not only experience that determines the quality of work. The best professionals stand out thanks to a set of specific skills - both technical and organizational. These are what make structures repeatable and precise, and the work fast and safe. Find out which competencies really make a difference and how to develop them in practice using GPPH solutions.

1. Precision and repeatability of workmanship

A good welder can perfectly reproduce every component, whether they are doing it for the first or the hundredth time. The key is the ability to position the details precisely and maintain the geometry of the structure.

How to develop this skill?

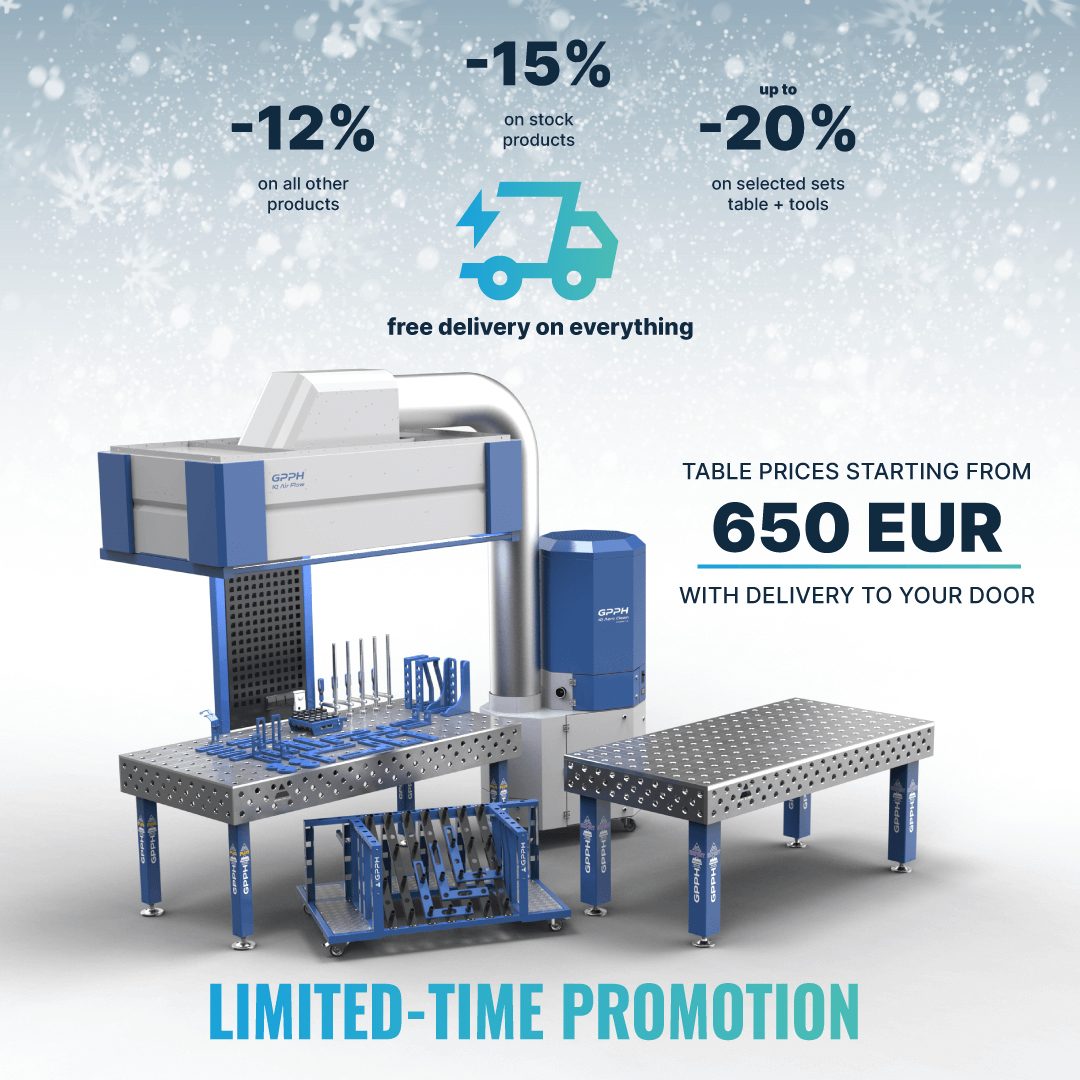

By working on GPPH welding tables, which provide a flatness tolerance of up to ≤ 0,3 mm (less than or equal to 0,3 mm) over the entire surface of the tabletop, as well as dense ribbing that guarantees stability. A 100x100 mm hole grid (and diagonal and 50x50 mm layouts, depending on the series) makes it possible to create clamping setups that eliminate positioning errors.

The result? The work becomes much more predictable and accurate.

2. Skillful organization of the workstation

Najlepsi spawacze wiedzą, że porządek to nie tylko estetyka to realna oszczędność czasu i bezpieczeństwo.

How to develop this skill?

By using solutions that organize tools and accessories, such as:

- WELDSTATION - complete welding station with drawers

- drawer sets and lower shelves mounted under the tables,

- Tool trolleys in two variants, M and L

The result? Thanks to them, every tool is exactly where it should be - always at hand and within sight.

3. Awareness of occupational safety and hygiene

A good welder understands that taking care of their health is just as important as weld quality. Proper ventilation, correct working posture and eliminating the risk of burns or injuries are part of the everyday standard.

How to develop this skill?

Sięgając po profesjonalne rozwiązania BHP:

- Okap GPPH IQ Air Flow, which effectively extracts welding fumes from the entire surface of the table, even from the corners.

- GPPH IQ Aero Clean – cleans the air of exhaust gases, dust and welding fumes, improving the quality of the working environment throughout the entire workshop.

- SOG grinding and welding workstations with bottom and top extraction, providing a clean working area.

The result? Thanks to such systems, the welder works more safely, more cleanly and more efficiently.

4. Ability to work with different materials

A welder who can work with mild steel, stainless steel and aluminium is much more versatile.

How to develop this skill?

By choosing equipment that does not hold them back, for example:

- INOX tables with corrosion-resistant tops,

- stainless steel overlays for traditional tables, ideal for working on stainless steel without the risk of corrosion hotspots.

The result? Changing the material does not have to mean changing the workstation - the right table is all you need.

5. Effective use of tools and supporting solutions

From clamps and angle brackets to supports – the better a welder knows their tools, the faster and more precisely they build structures.

How to develop this skill?

Regularnie korzystając z:

- tool sets, e.g. S, XS, PRO, PLUS, matched to the type of table,

- TRESTLE supports, which increase the working area and make work on large structures easier,

- blocks and connectors that make it possible to create non-standard workstations and spatial (three-dimensional) structures.

The result? These are tools that make the work faster, more repeatable and much more intuitive.

A good welder is not only a master of welds, but also a professional who understands the importance of precision, organisation and safety. Each of the five key skills can be continuously developed, and with well-chosen tables, accessories and solutions from GPPH, this development becomes a natural part of everyday work.